Electrical First Restoration

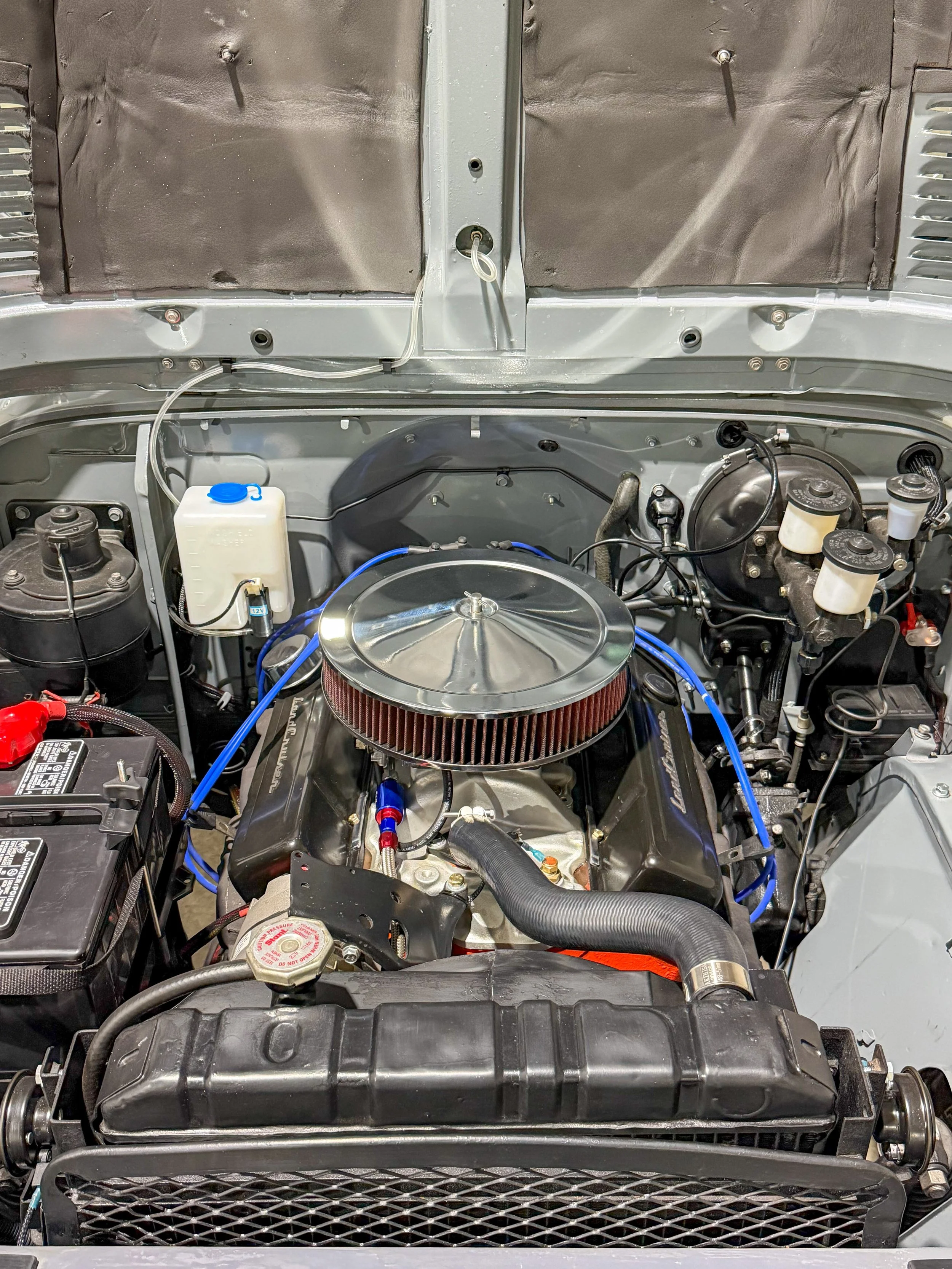

Project Sun Cruiser was undertaken with a singular goal: to transform a classic FJ40 into a fully dependable, electrically modernized Land Cruiser while preserving its original mechanical character. Rather than chasing cosmetic excess or drivetrain reinvention, this build focused on the backbone of long-term reliability—a ground-up electrical and systems replacement.

Mechanical Verification

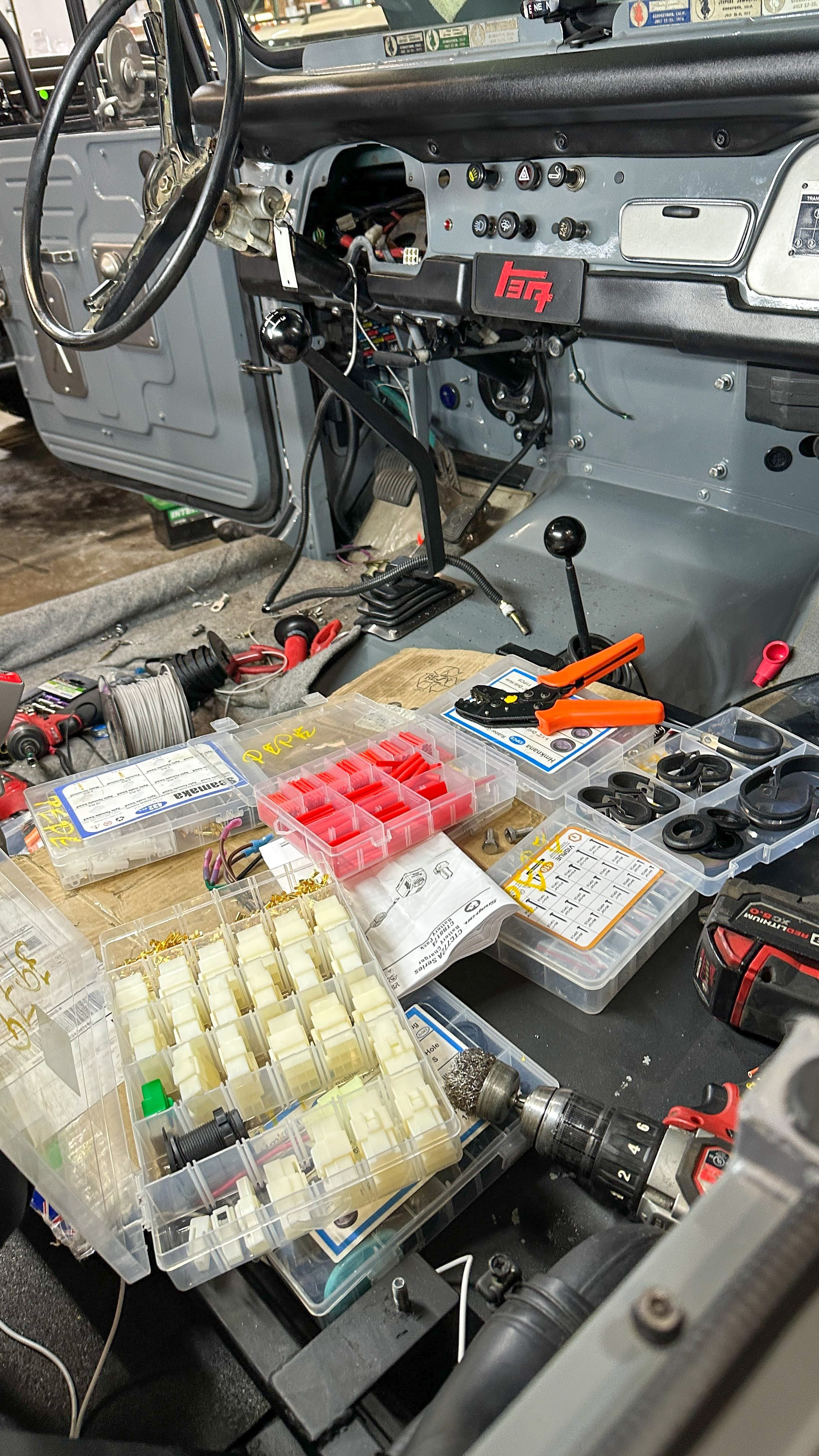

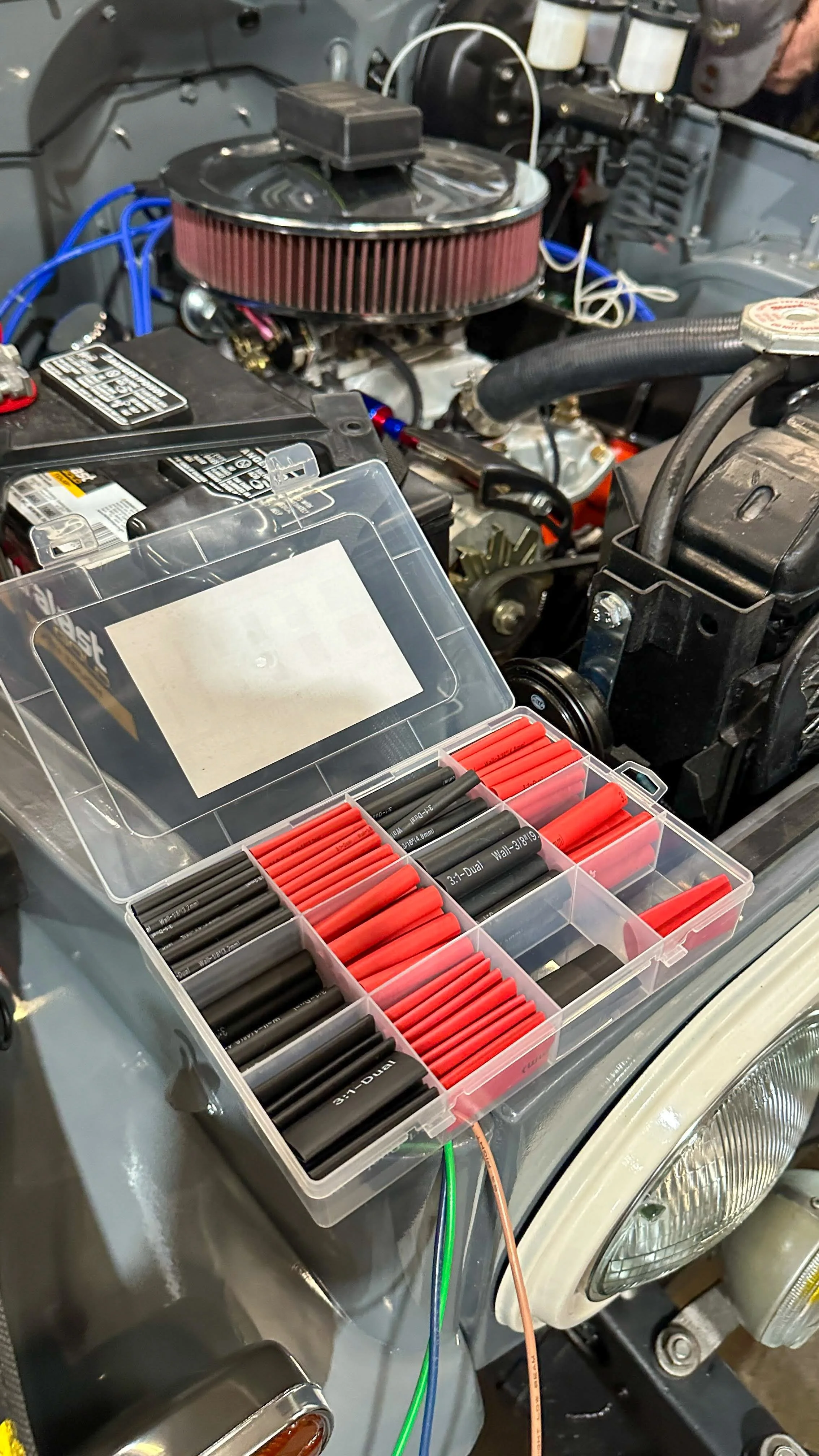

Vintage Land Cruisers are defined as much by their simplicity as by their weaknesses, and electrical integrity is often the limiting factor in real-world usability. Sun Cruiser addresses that head-on. Every circuit, harness, relay, and switch was rethought, rebuilt, and reinstalled with modern logic and serviceability in mind—bringing clarity, consistency, and confidence to a platform originally designed decades ago.

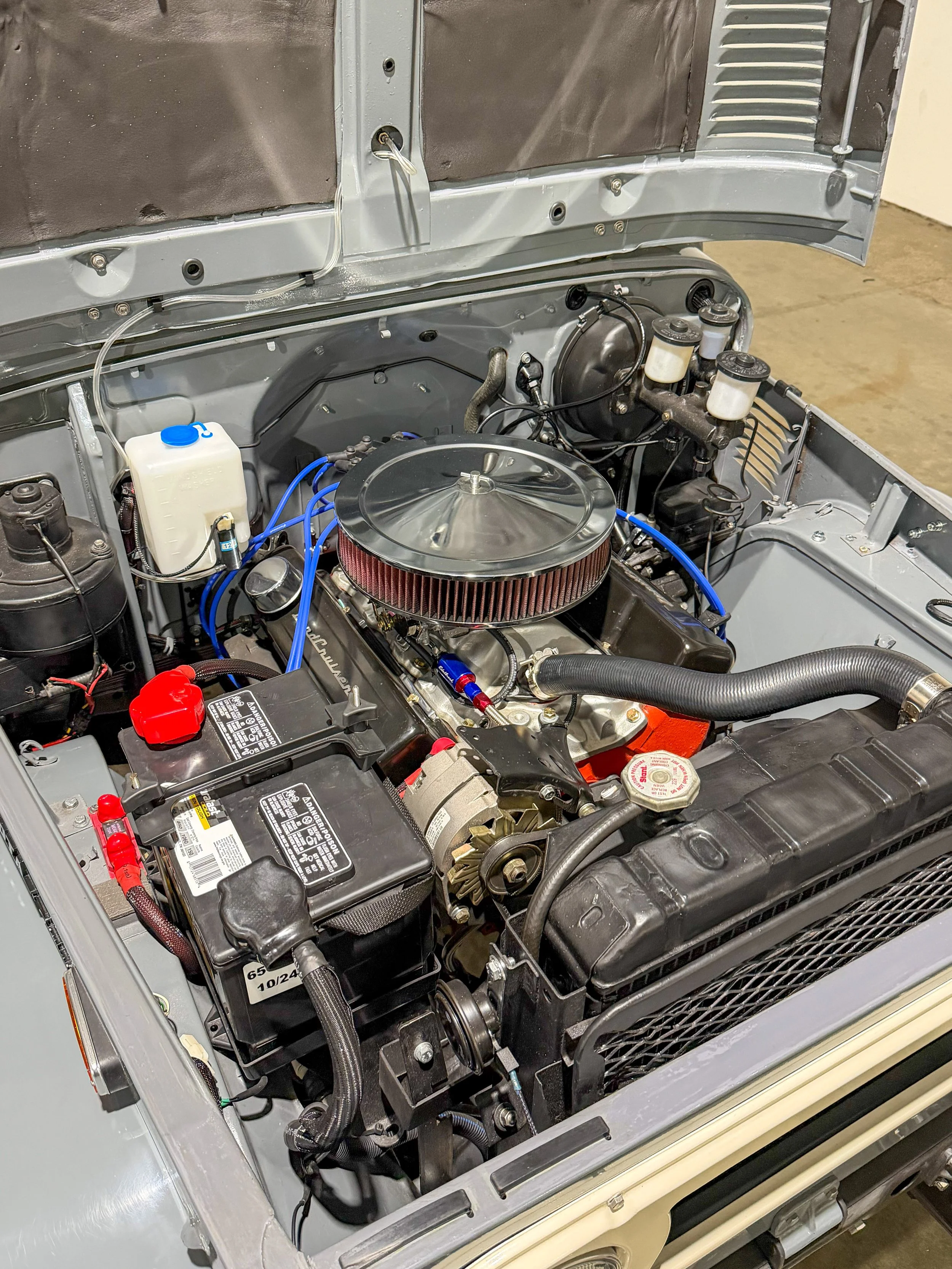

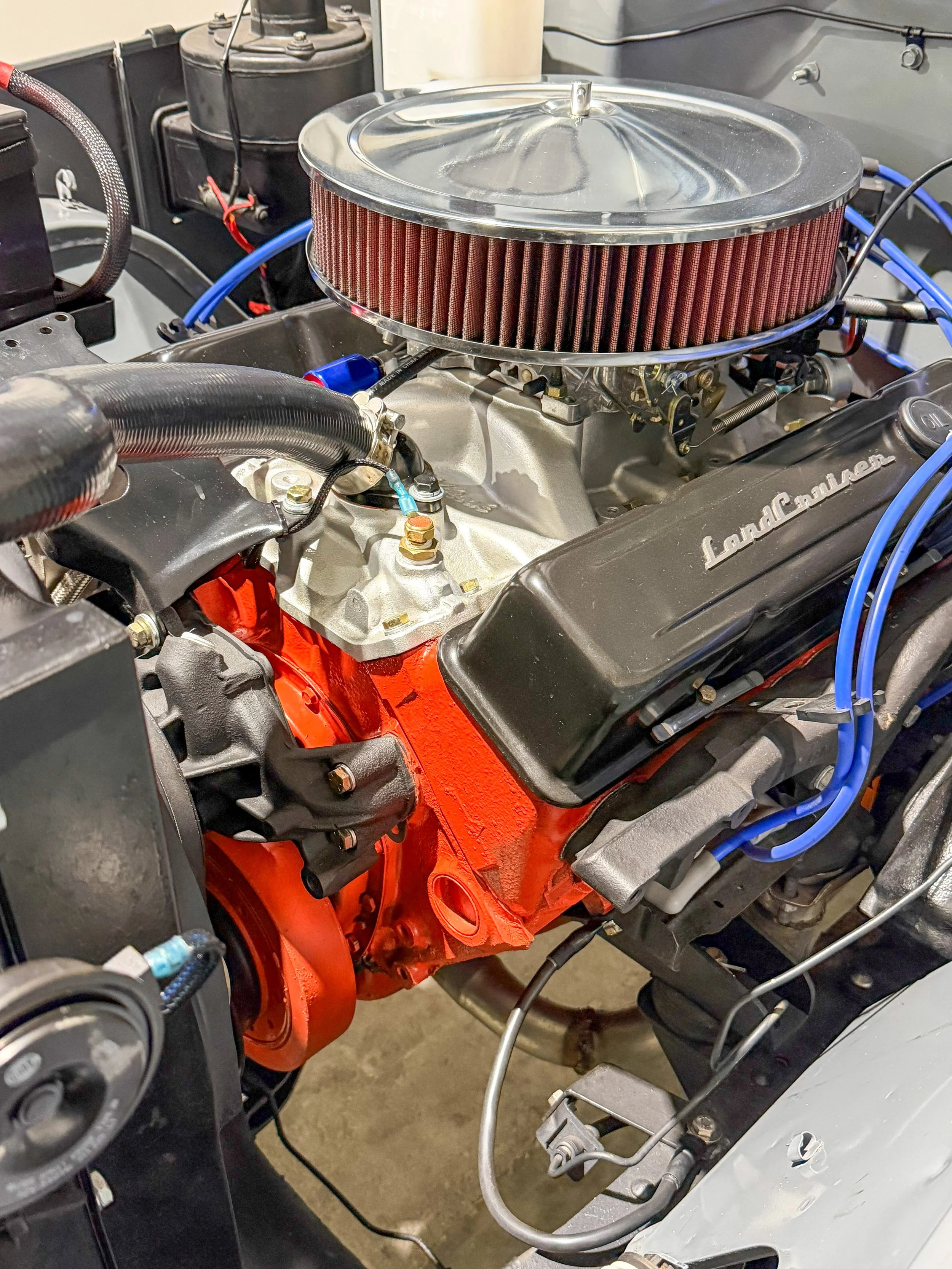

Mechanically, the vehicle was inspected, tuned, and verified to ensure it complemented the new electrical foundation. Interior systems, ventilation, gauges, and controls were carefully reintegrated so the truck retains its analog feel while functioning with modern dependability.

Project Sun Cruiser is not about visible transformation—it’s about trust. A Land Cruiser that starts, signals, cools, charges, and communicates exactly as it should, whether heading down a back road at sunrise or returning home long after dark.

Key Features :

1973 Toyota Land Cruiser FJ40 platform

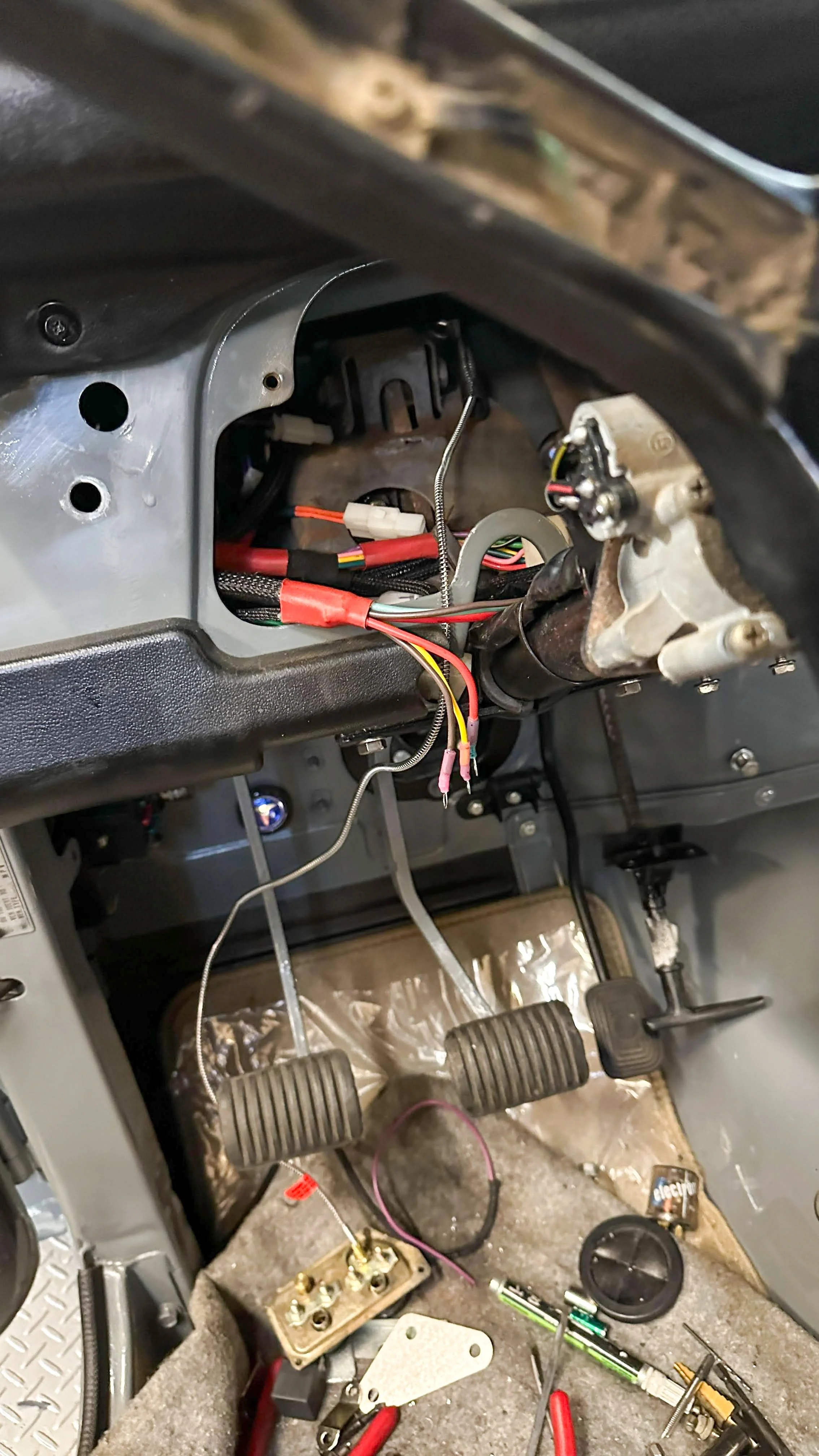

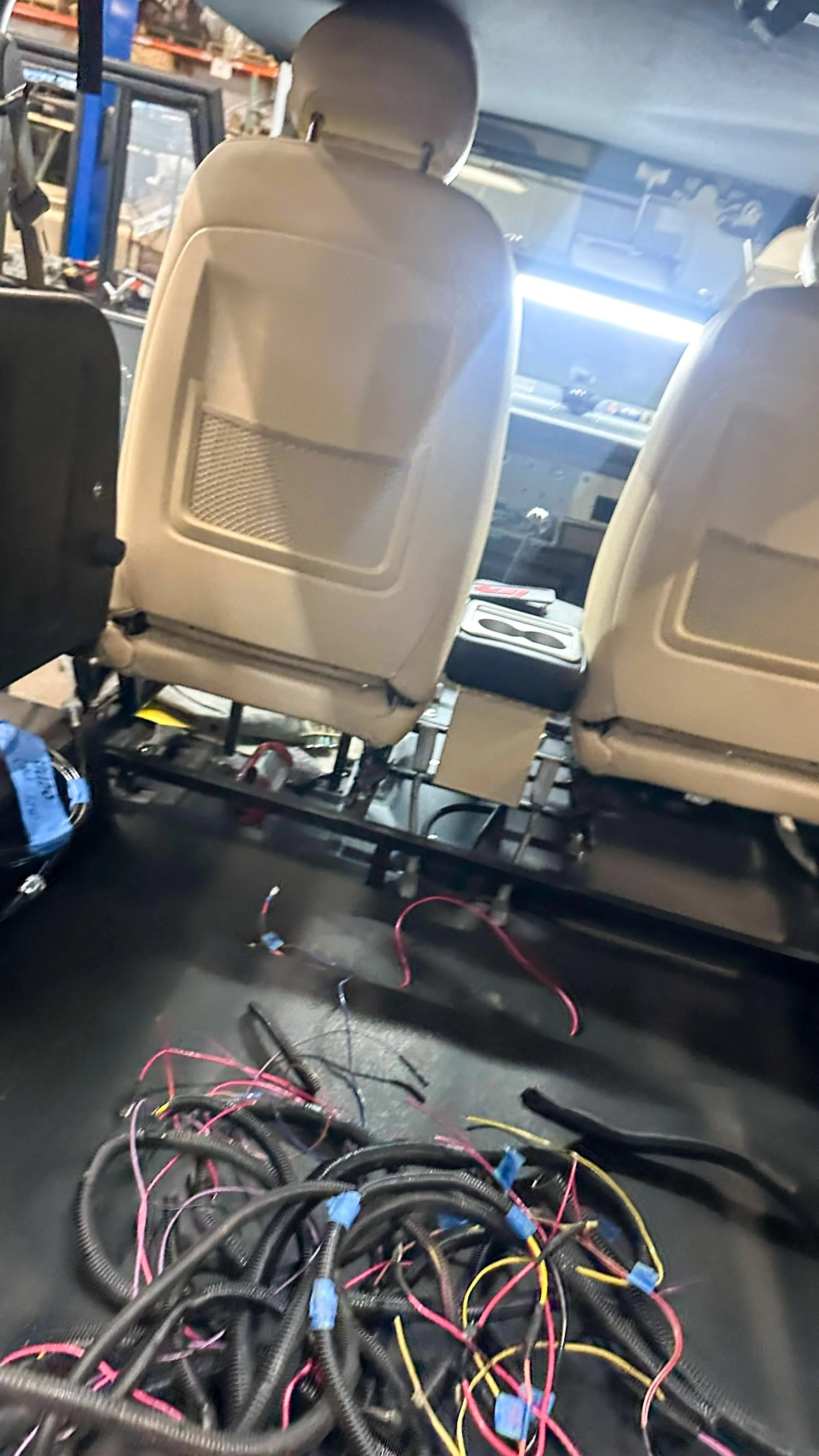

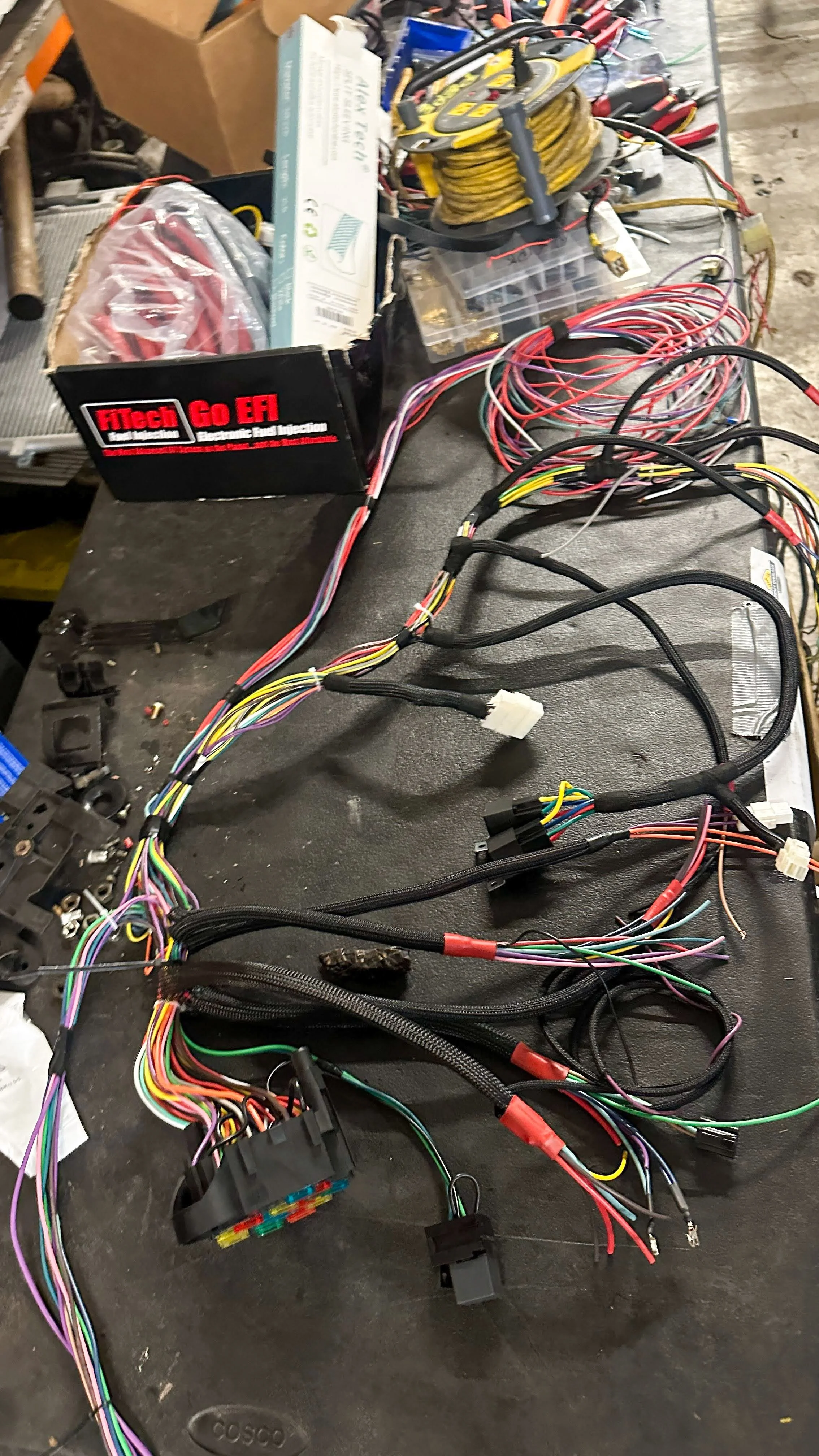

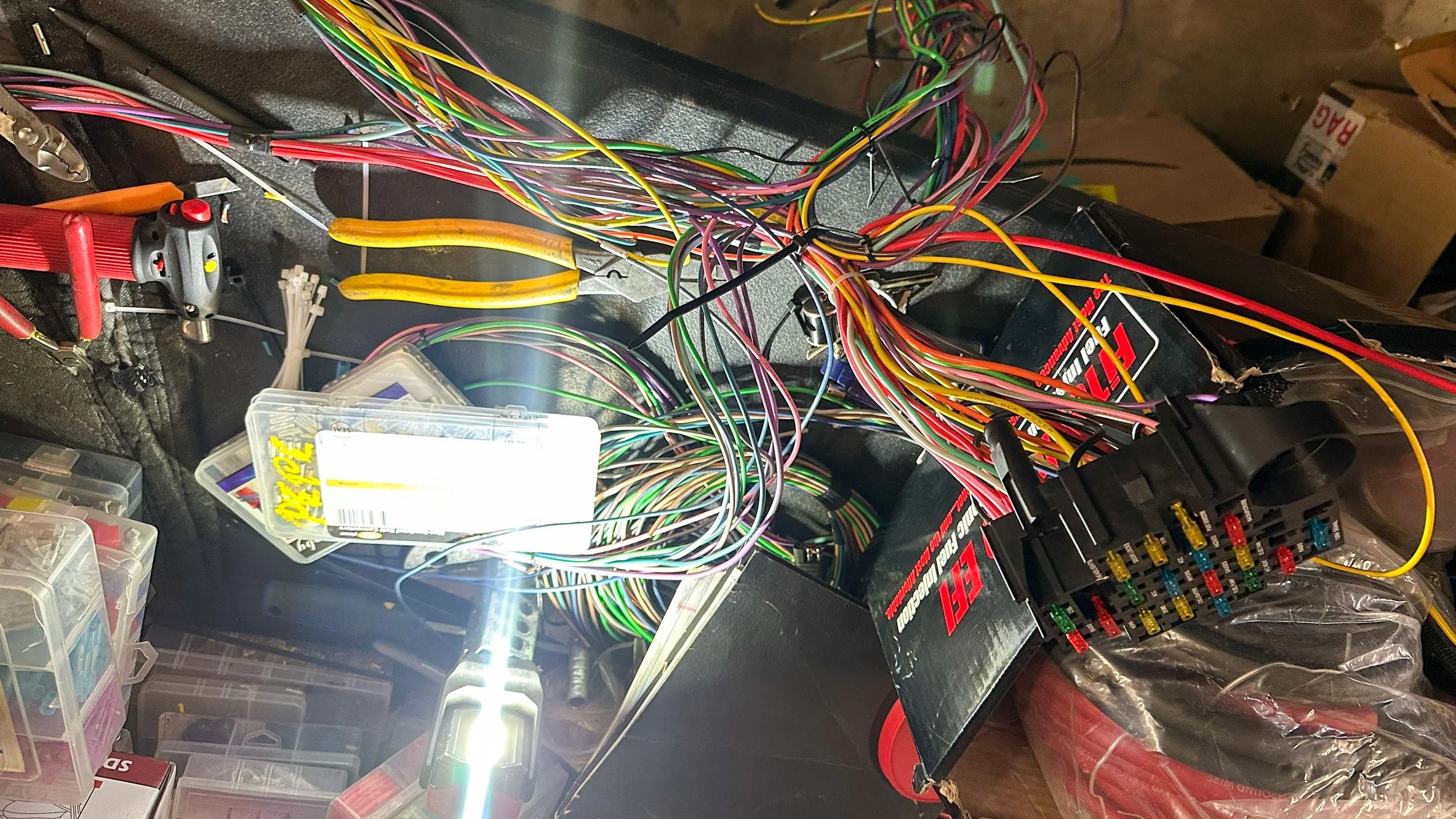

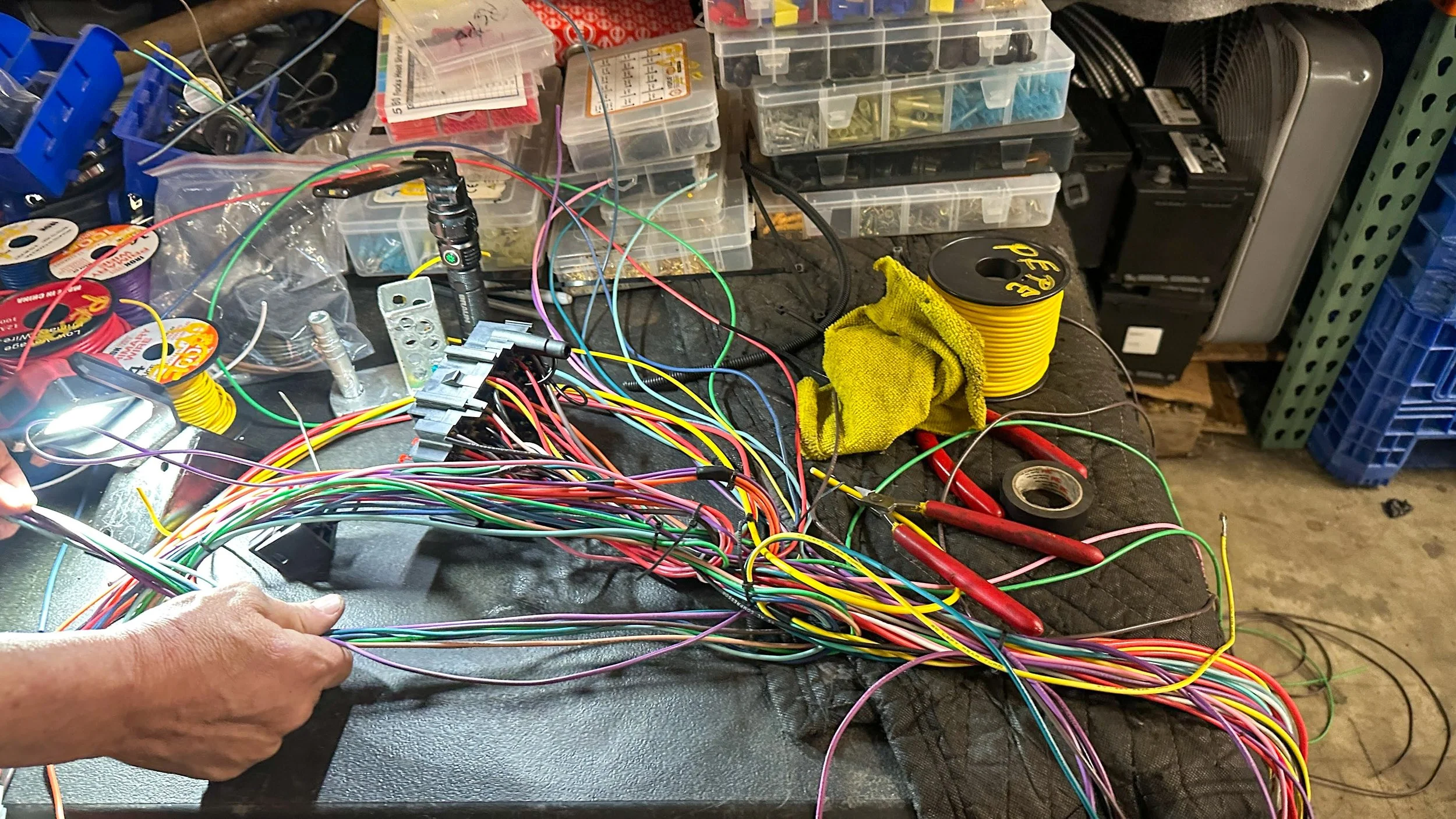

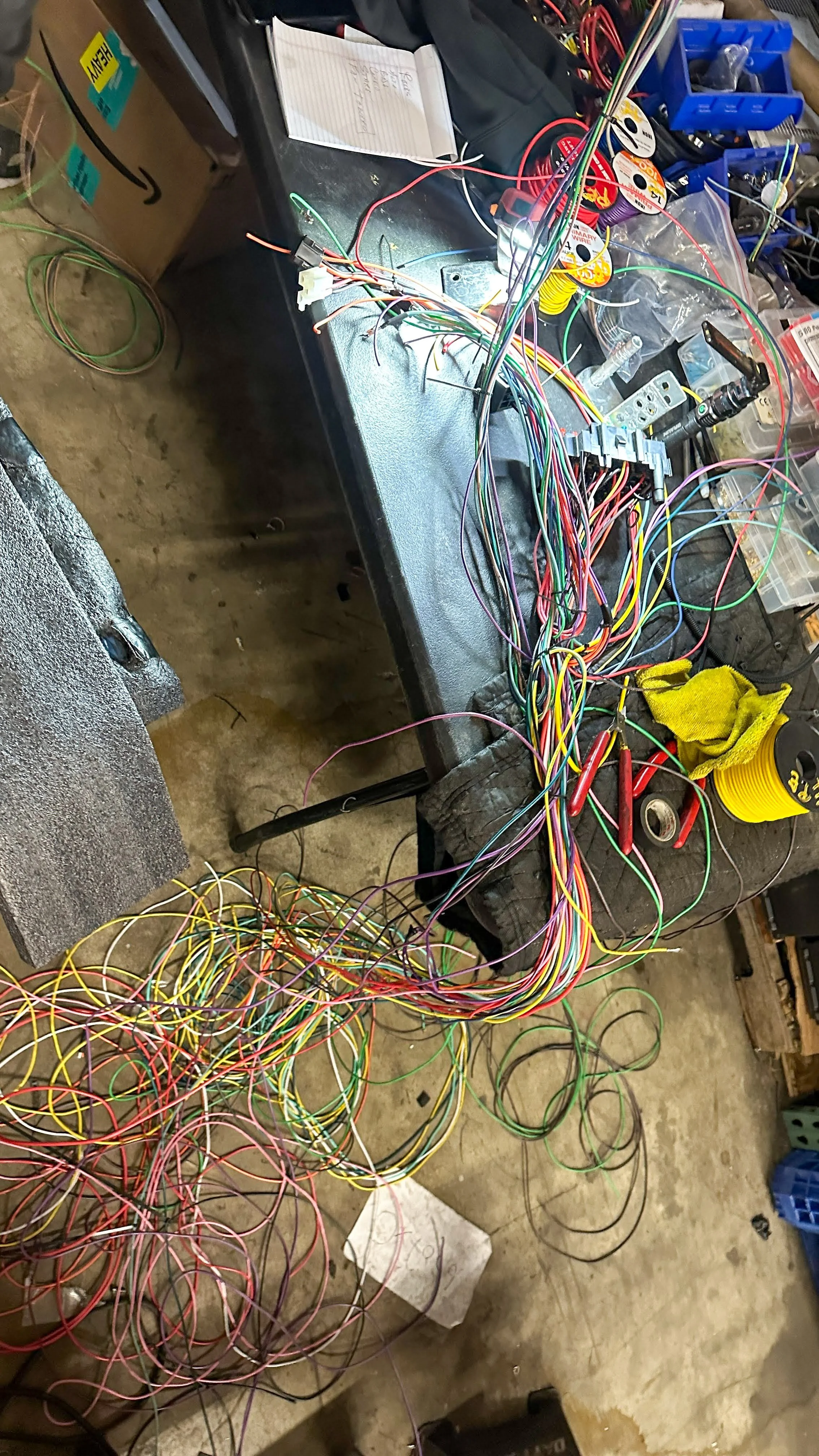

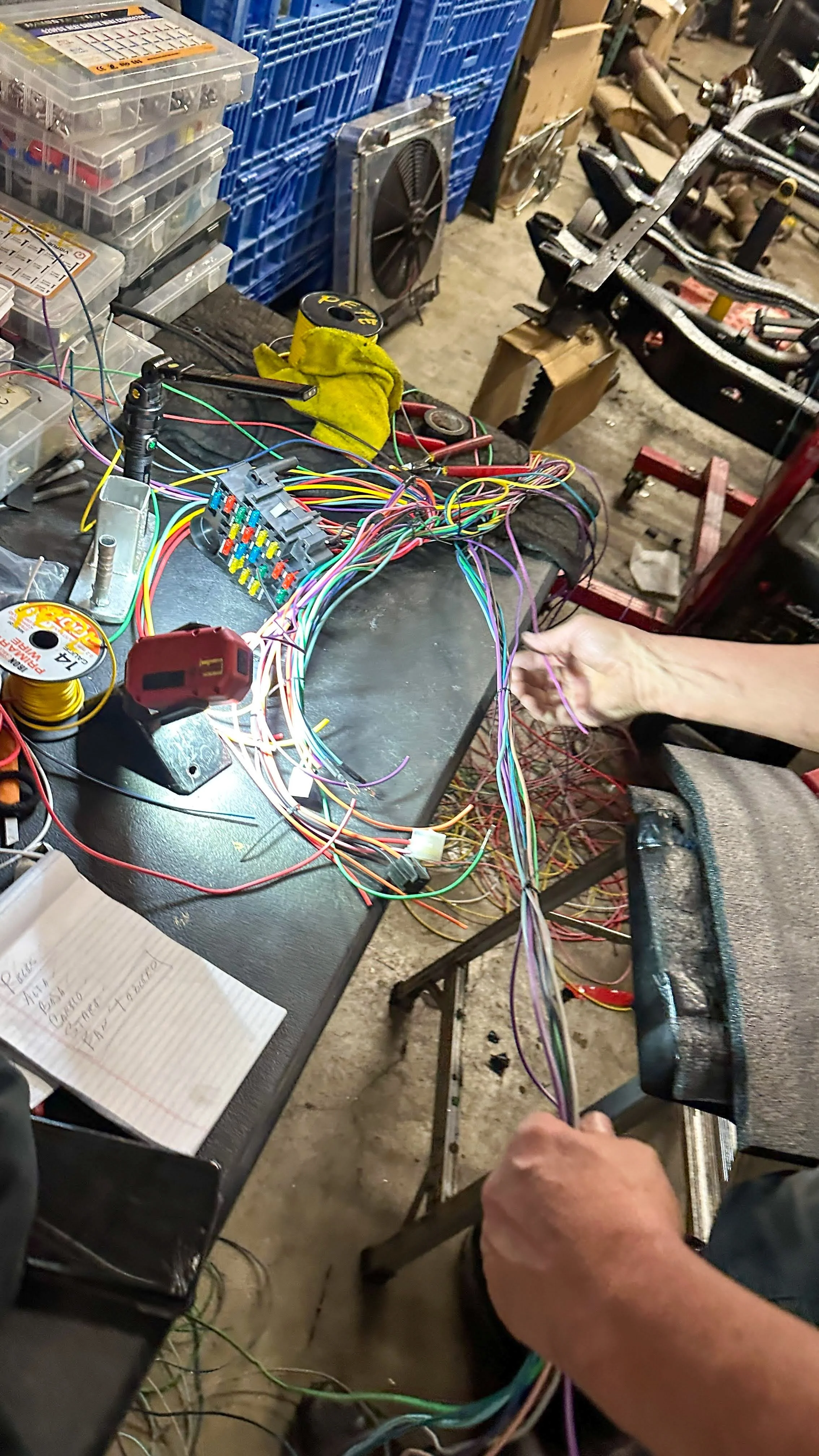

Complete vehicle electrical system redesign and rebuild

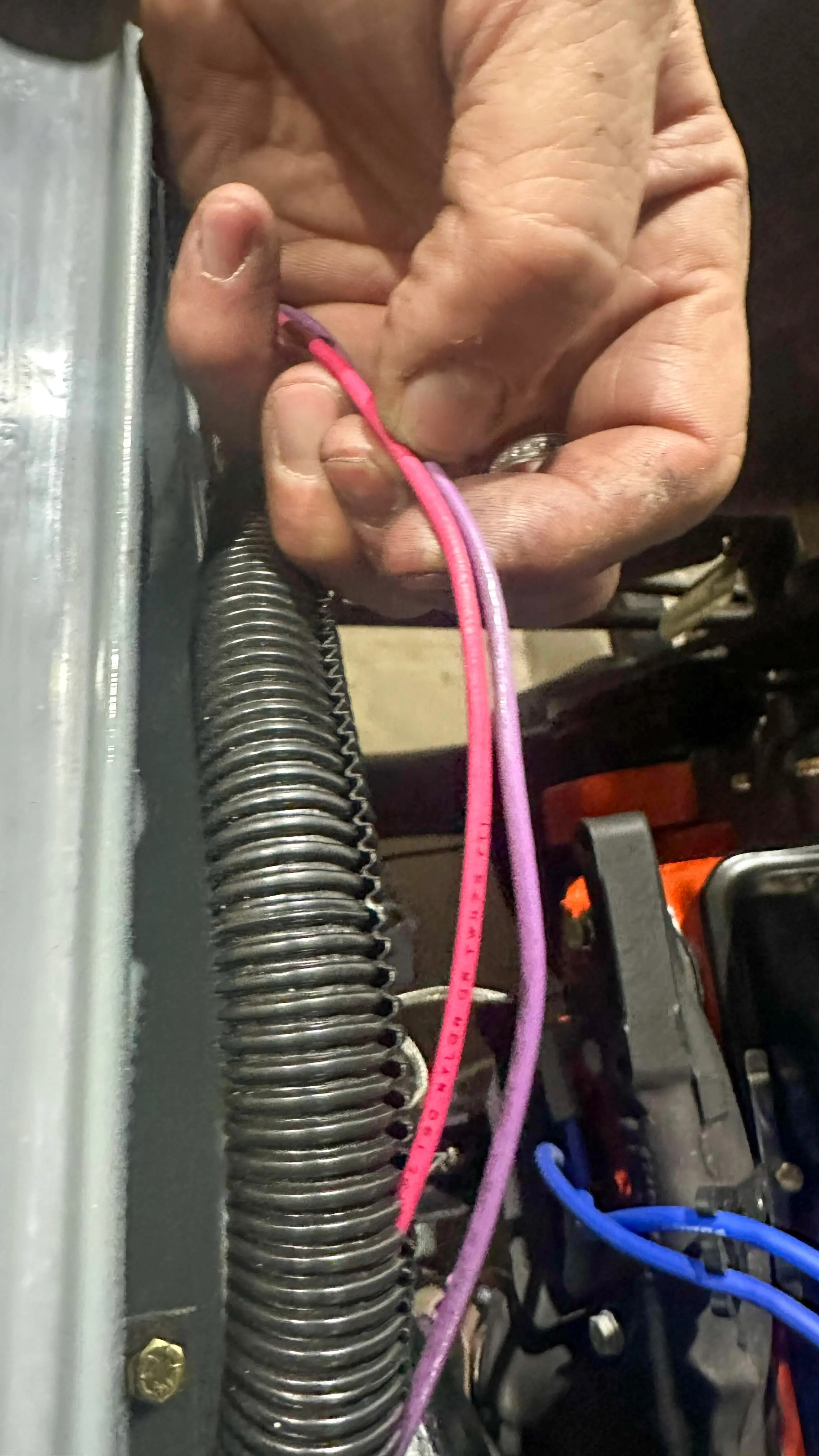

Custom front and rear wiring harness fabrication

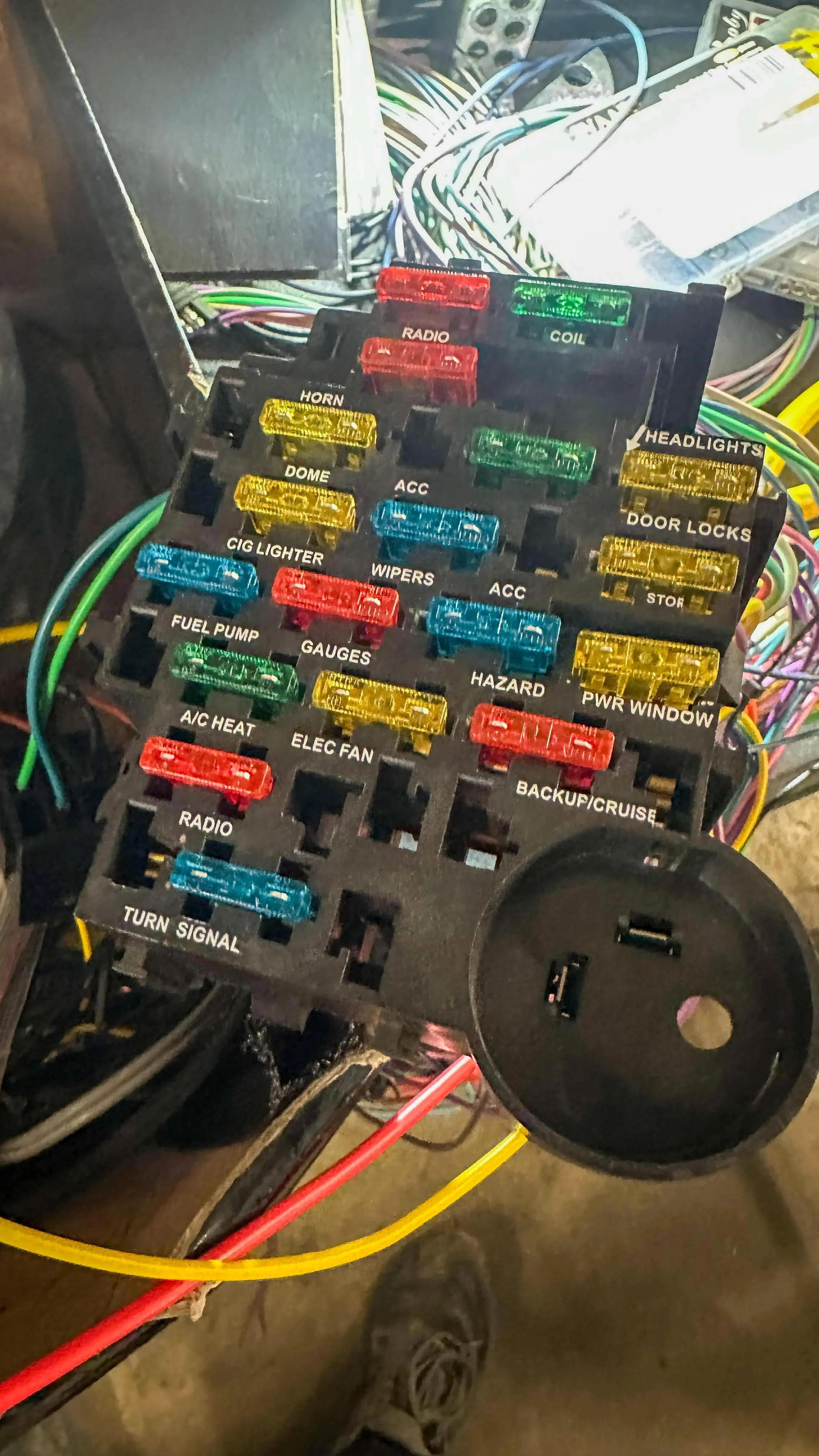

New centralized fuse and relay block system

Master battery disconnect and safety cut-off system

Rewired ignition, lighting, charging, and accessory circuits

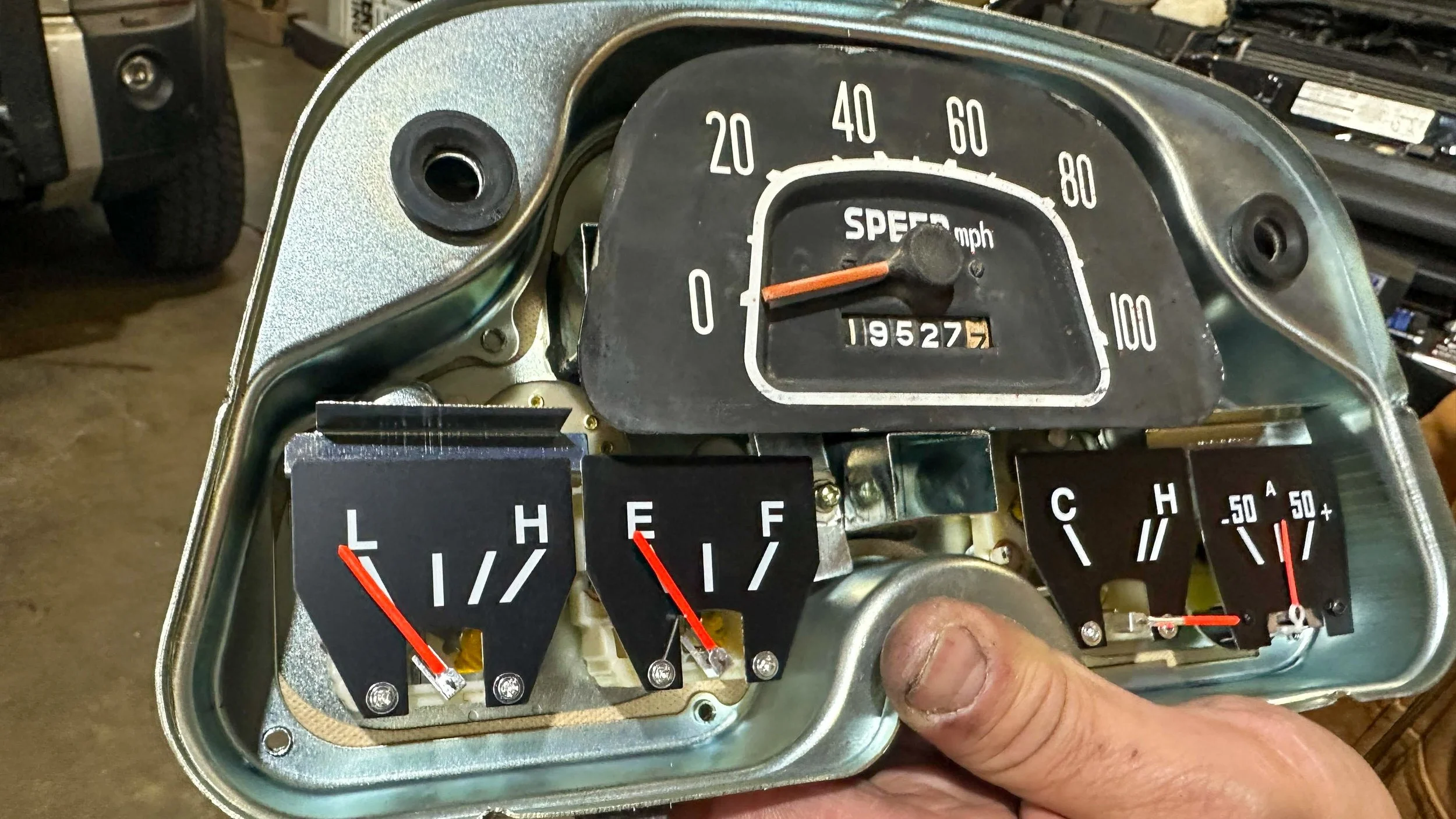

Custom gauge cluster integration with updated sensors

New oil pressure and coolant temperature sensors

Rebuilt and rewired lighting system (headlights, signals, brake lights)

Electric fan wiring and relay integration

Windshield wiper system rewired with new relays and switches

Horn, hazard, and emergency lighting circuits rebuilt

Cabin switchgear rewired and integrated into new harness

Ventilation and heater system rebuilt and electrically integrated

Battery cabling, grounds, and power distribution redesigned

Reverse light switch and wiring added

Brake light switch and safety circuits renewed

Carburetor tuning and ignition timing adjustment

Fuel system inspection and verification

Full nut-and-bolt, electrical, and functional inspection completed