A Legacy Overland Refinement of a Fresh Restoration

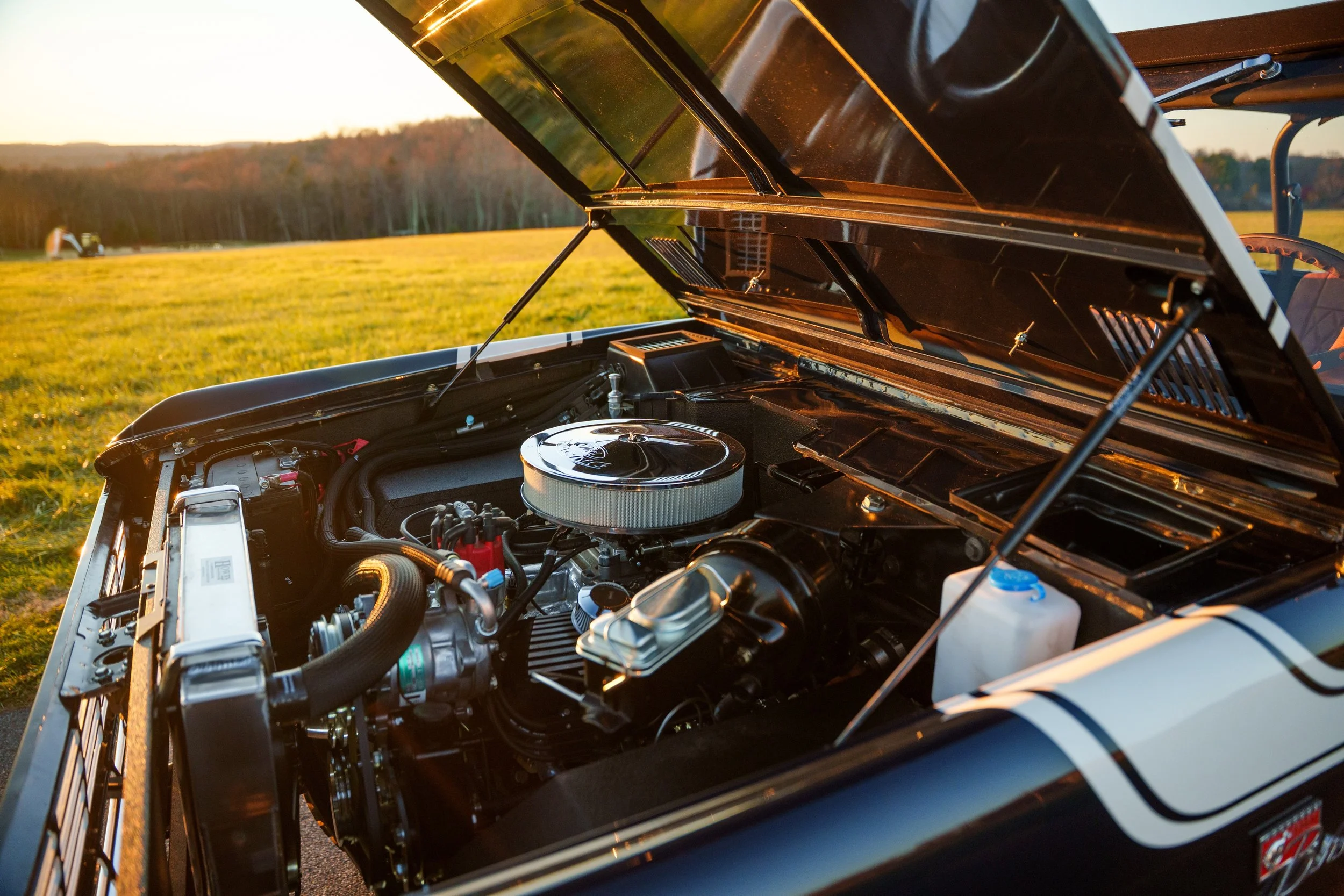

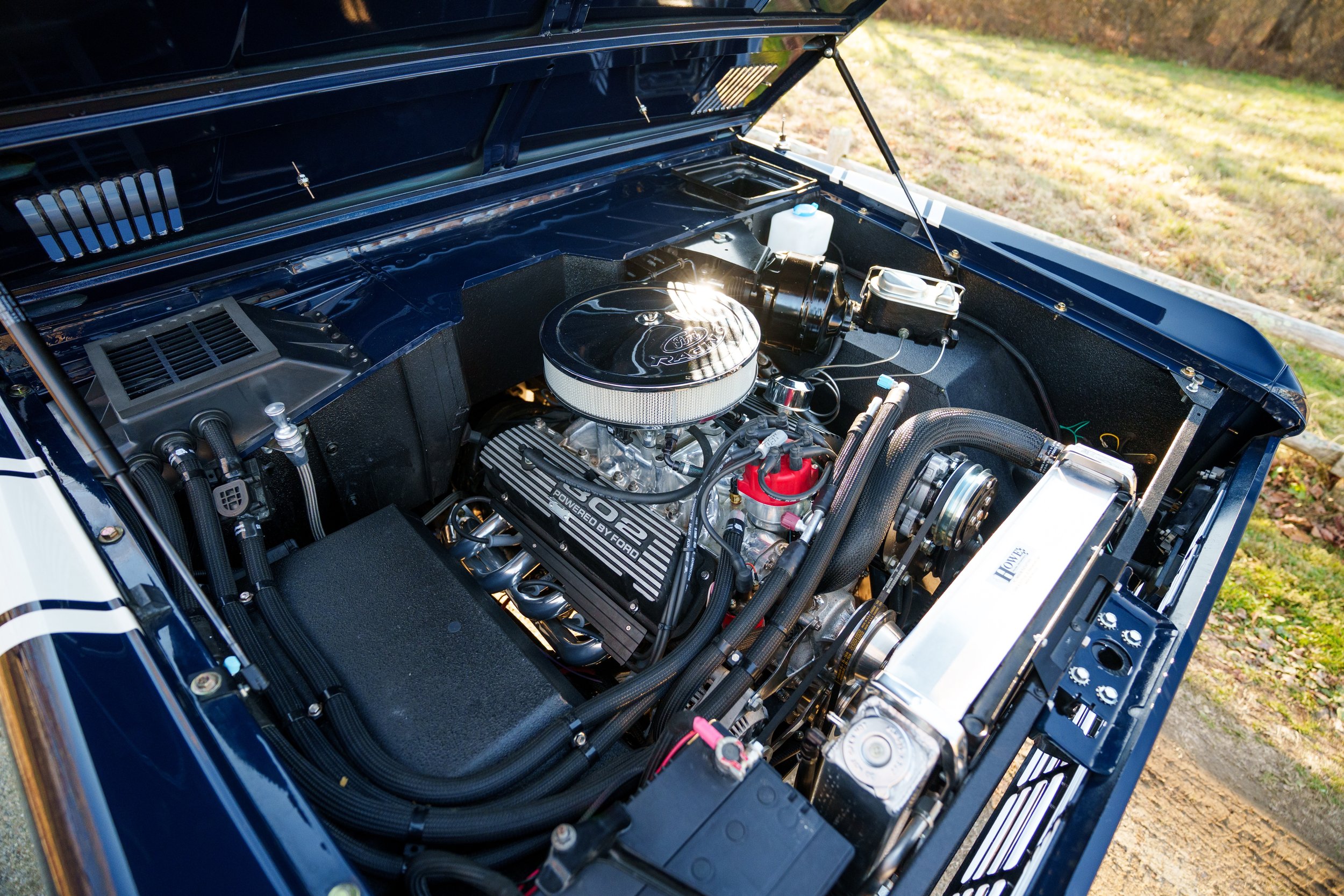

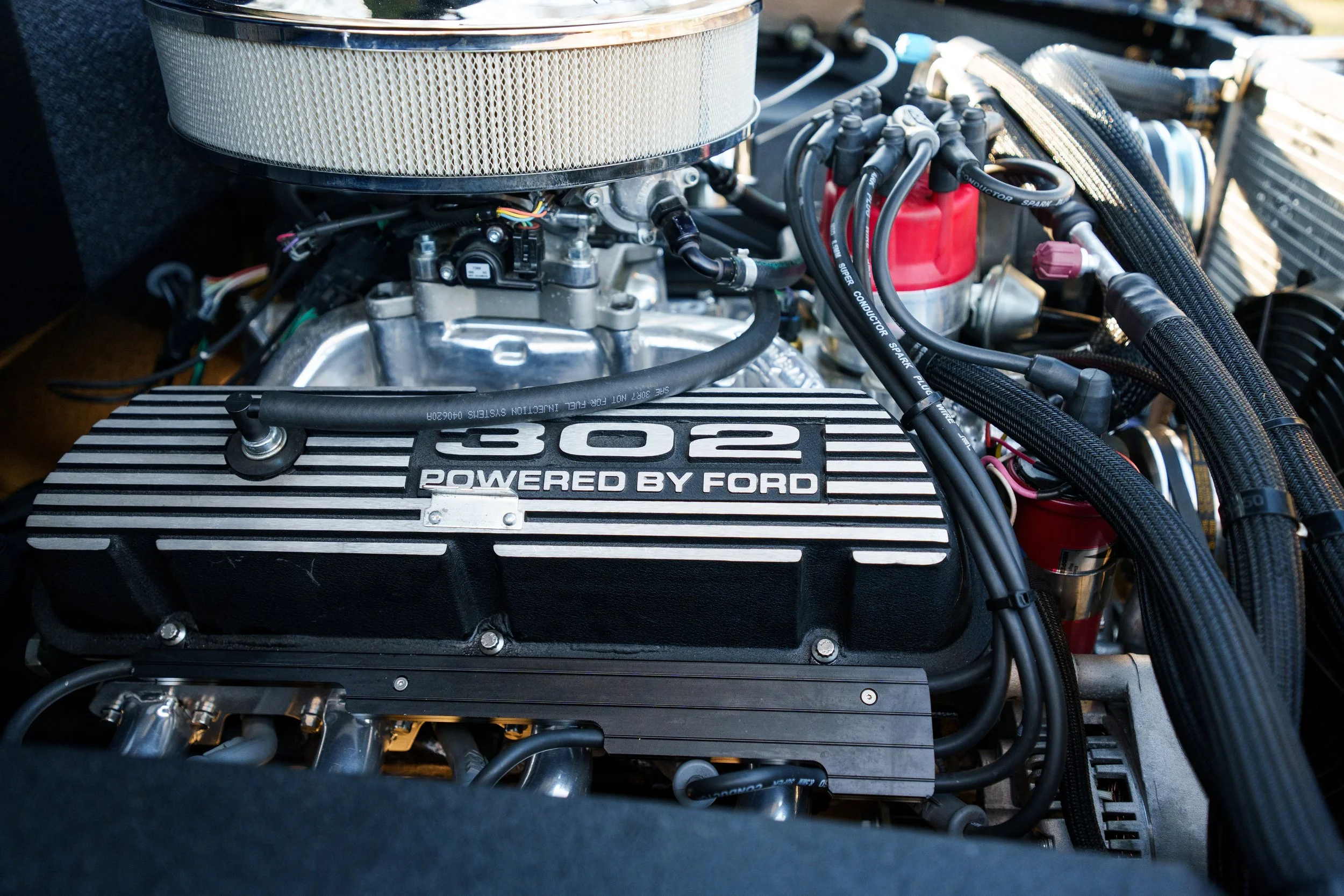

Every so often, a classic arrives already wearing fresh paint and new parts—clearly loved, earnestly restored, yet missing that last layer of polish and craftsmanship that transforms a good truck into a truly exceptional one. Project Moulton, a beautifully revived 1968 Ford Bronco, came to Legacy Overland in exactly that state. The soul was there, the work was mostly done, but the details—the things that make a classic Bronco feel cohesive, reliable, and correct—still needed attention.

Refined Execution

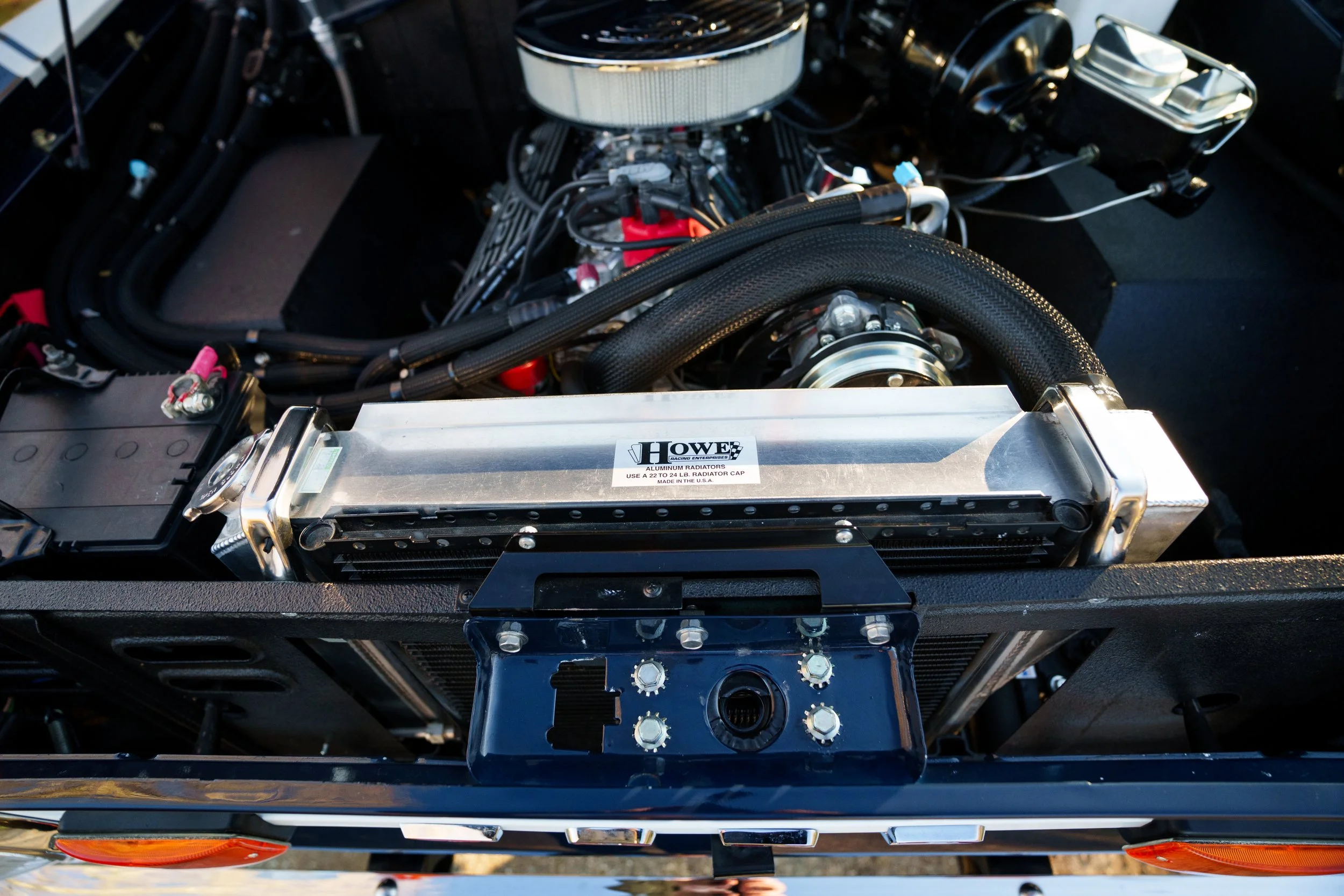

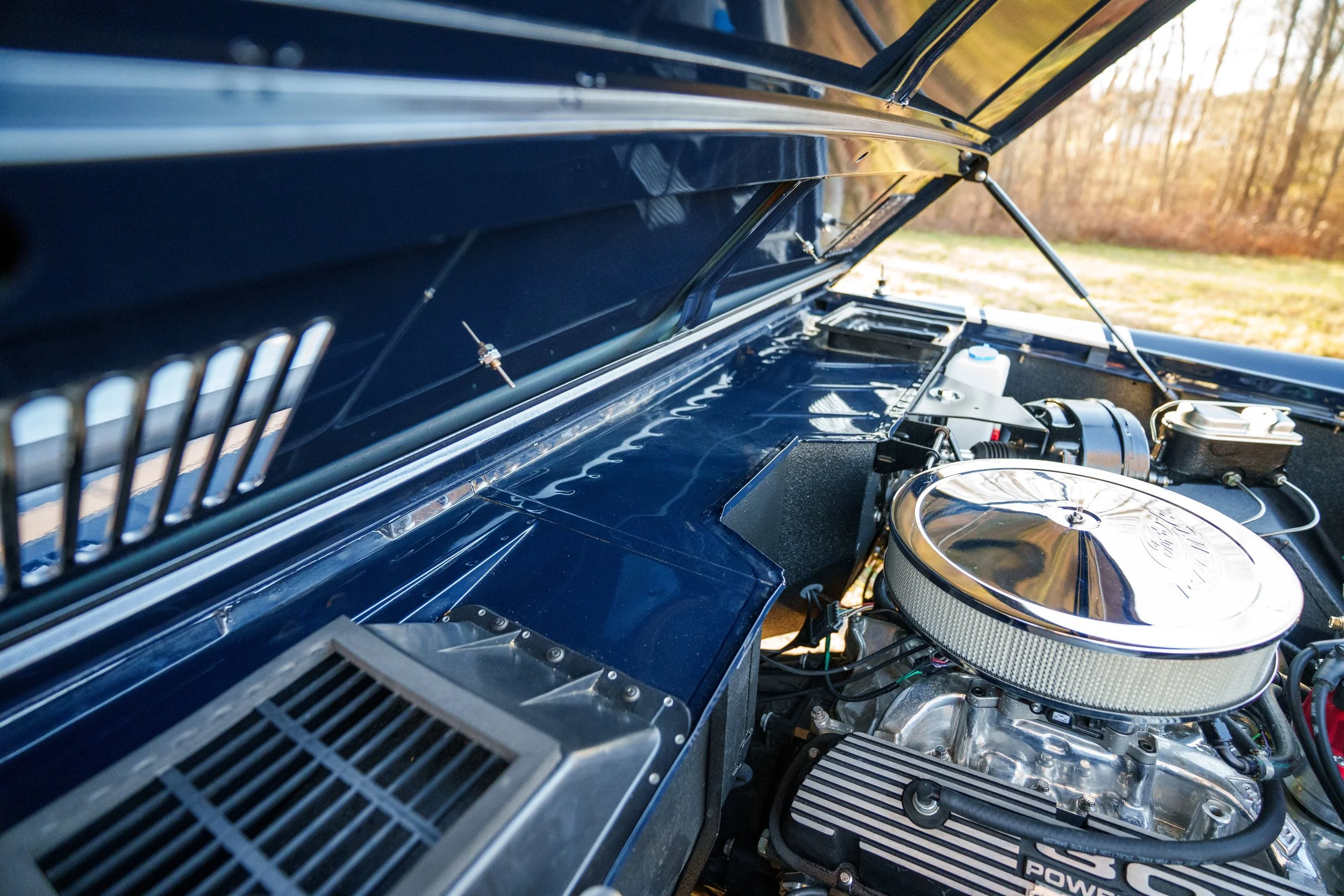

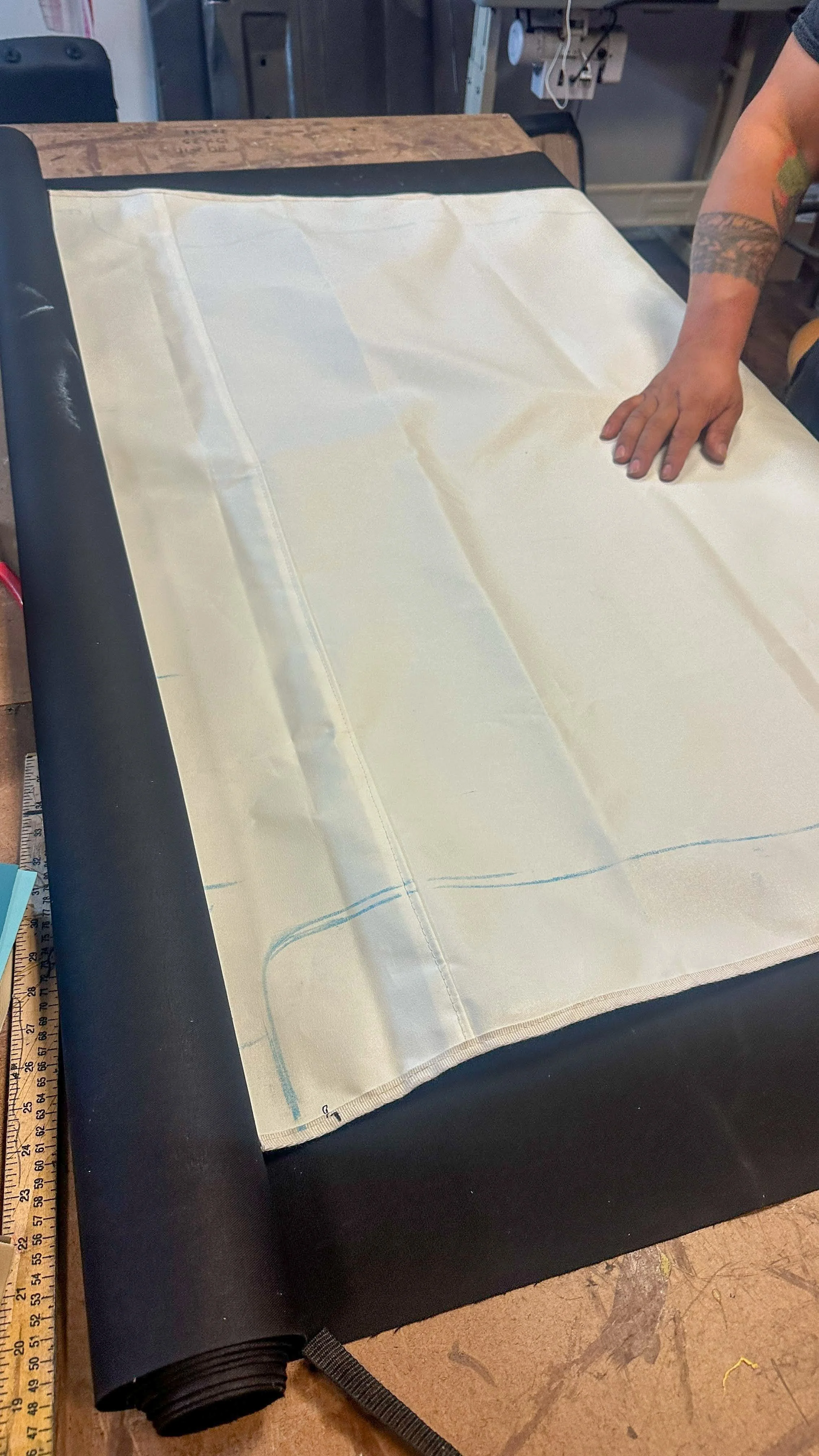

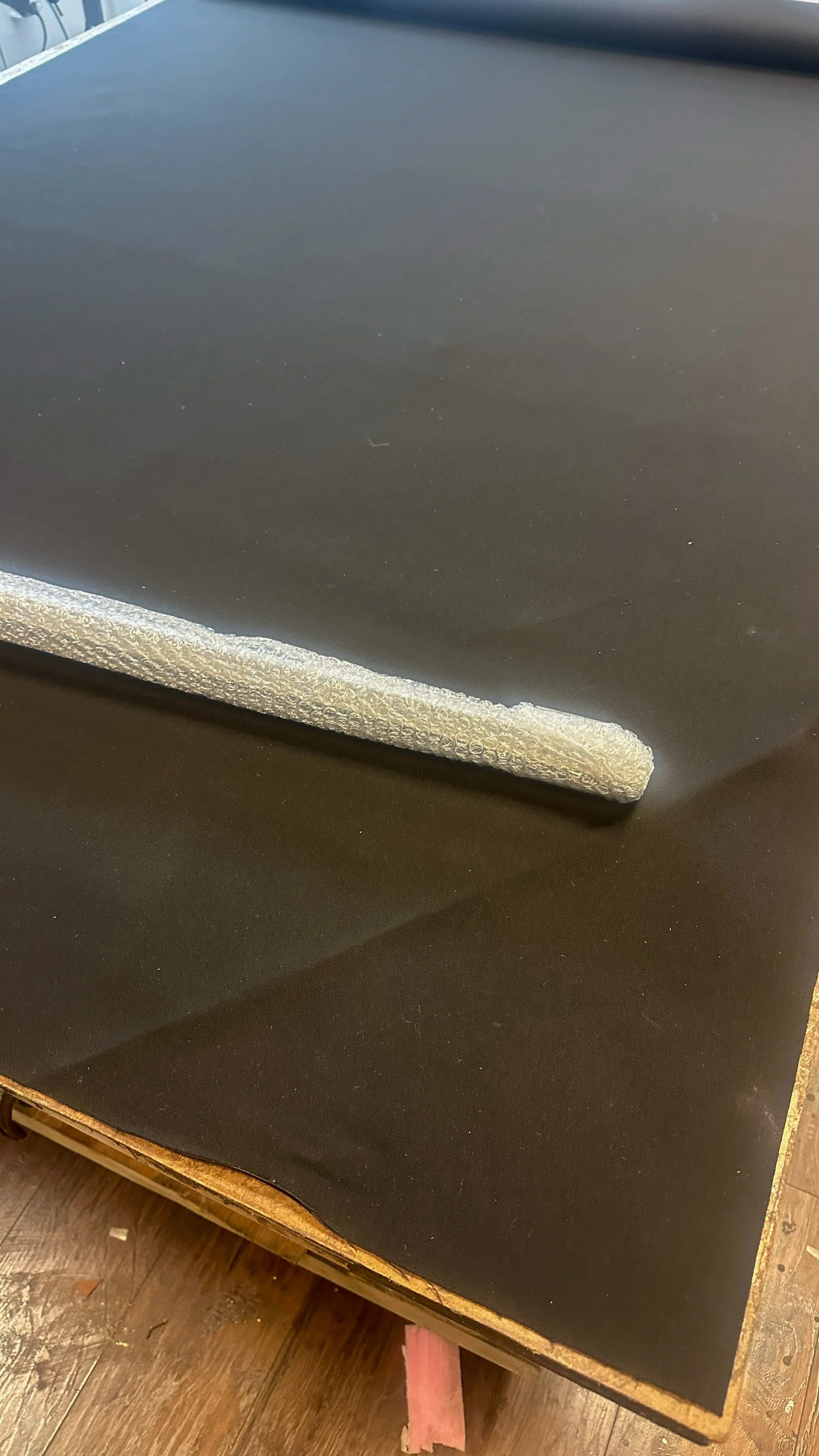

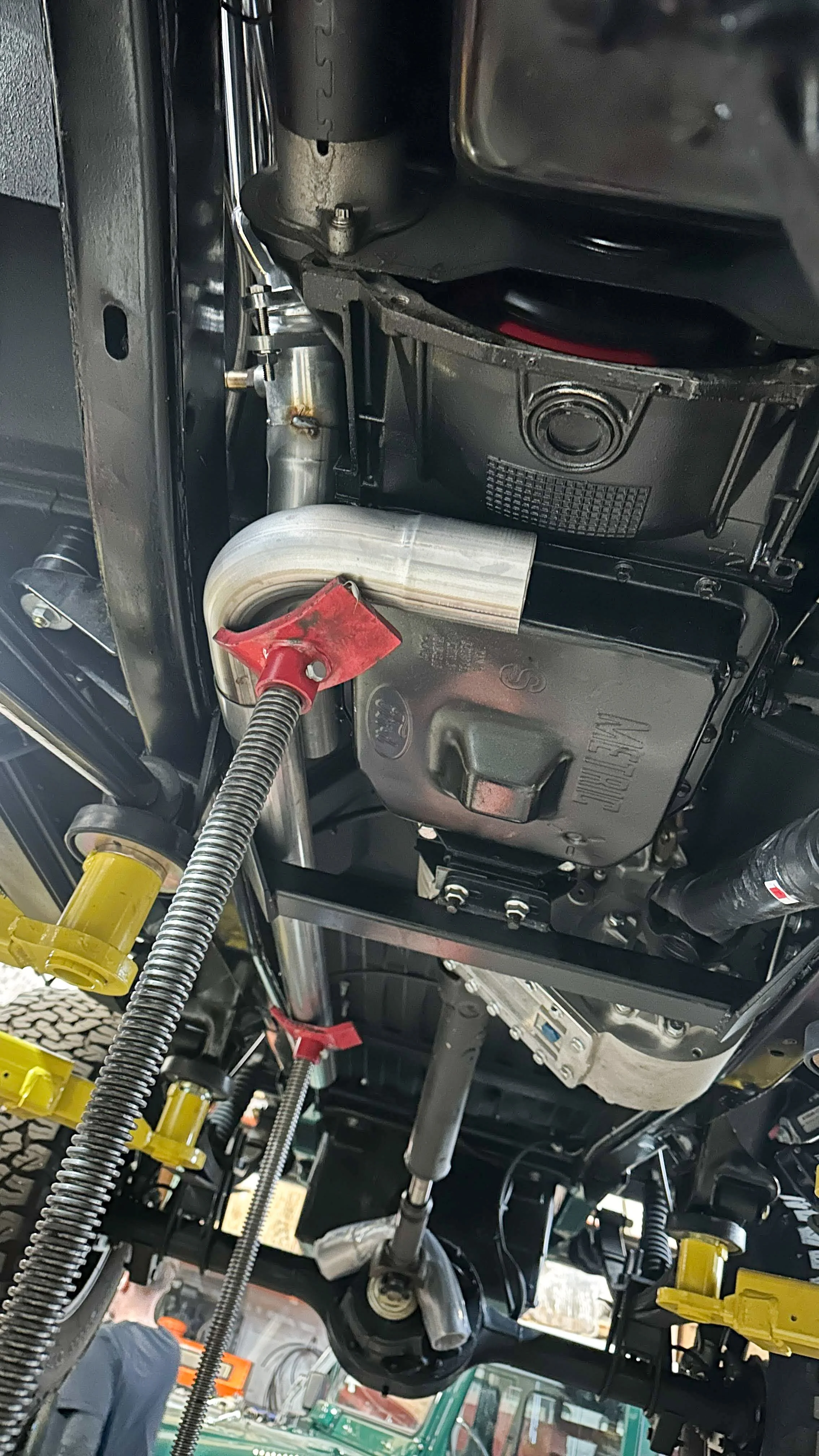

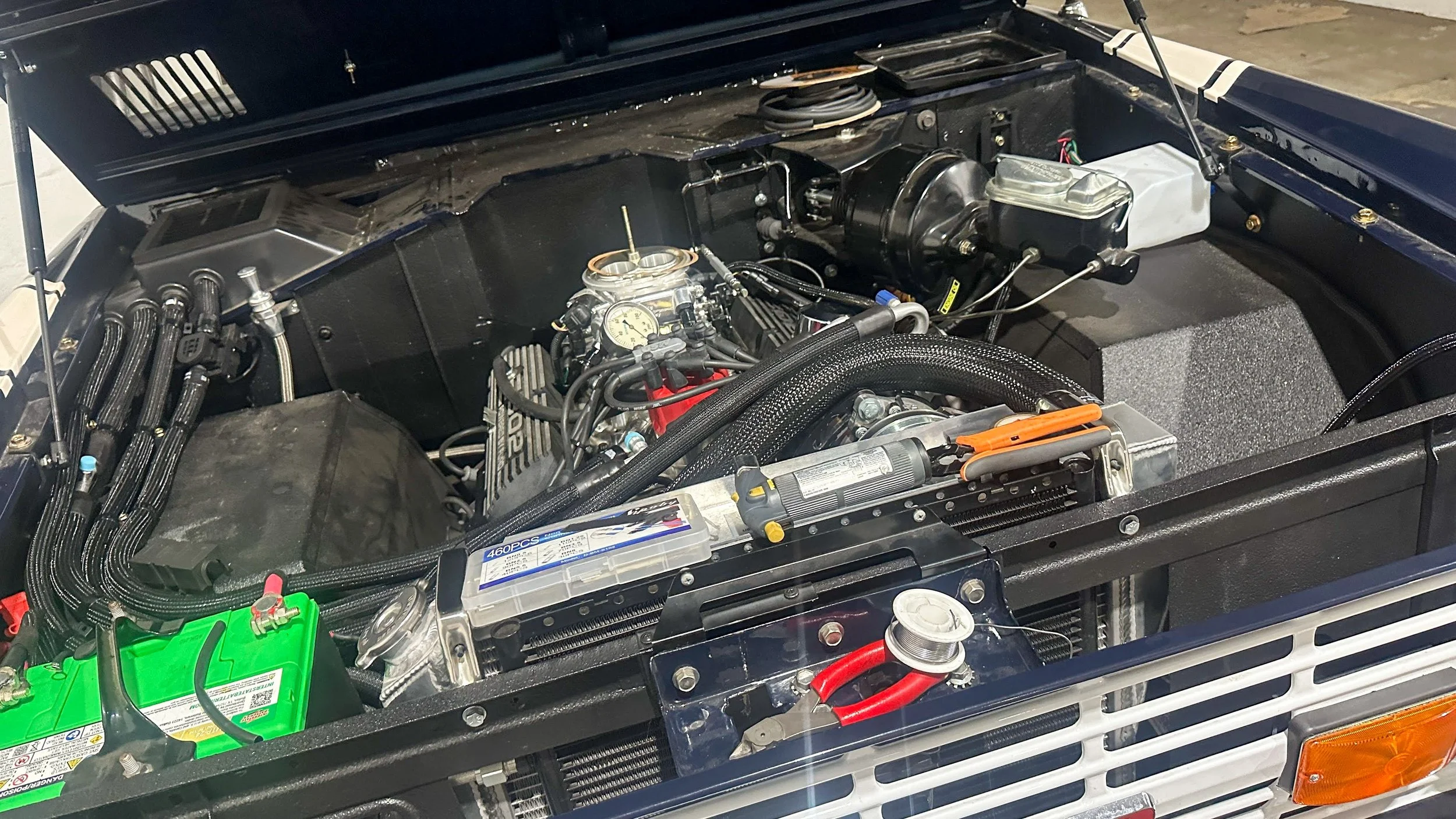

Our task wasn’t to rebuild Moulton. It was to perfect it. To take the foundation laid by its prior restoration and bring it up to Legacy Overland standards of drivability, reliability, fitment, and finish.This meant untying electrical knots hidden behind new panels. Correcting a heating and AC system that was plumbed but not functional. Replacing an exhaust that looked the part but didn’t perform or fit the way it should. And crafting a hand-built soft top—created from custom molds—to replace an aftermarket unit that simply didn’t honor the Bronco’s iconic proportions.

Today, Moulton stands as a refined example of what a first-generation Bronco should be: honest, simple, mechanical, and now—finally—finished the right way.

Highlights of the build:

Exterior

First-generation 1968 Ford Bronco body with refined fit and finish

Custom Legacy Overland soft top, hand-built from bespoke molds

Fresh canvas top with improved structure and sealing

Updated exterior electrical components (horns, wiring, connectors)

Reworked panel alignment and trim refinement

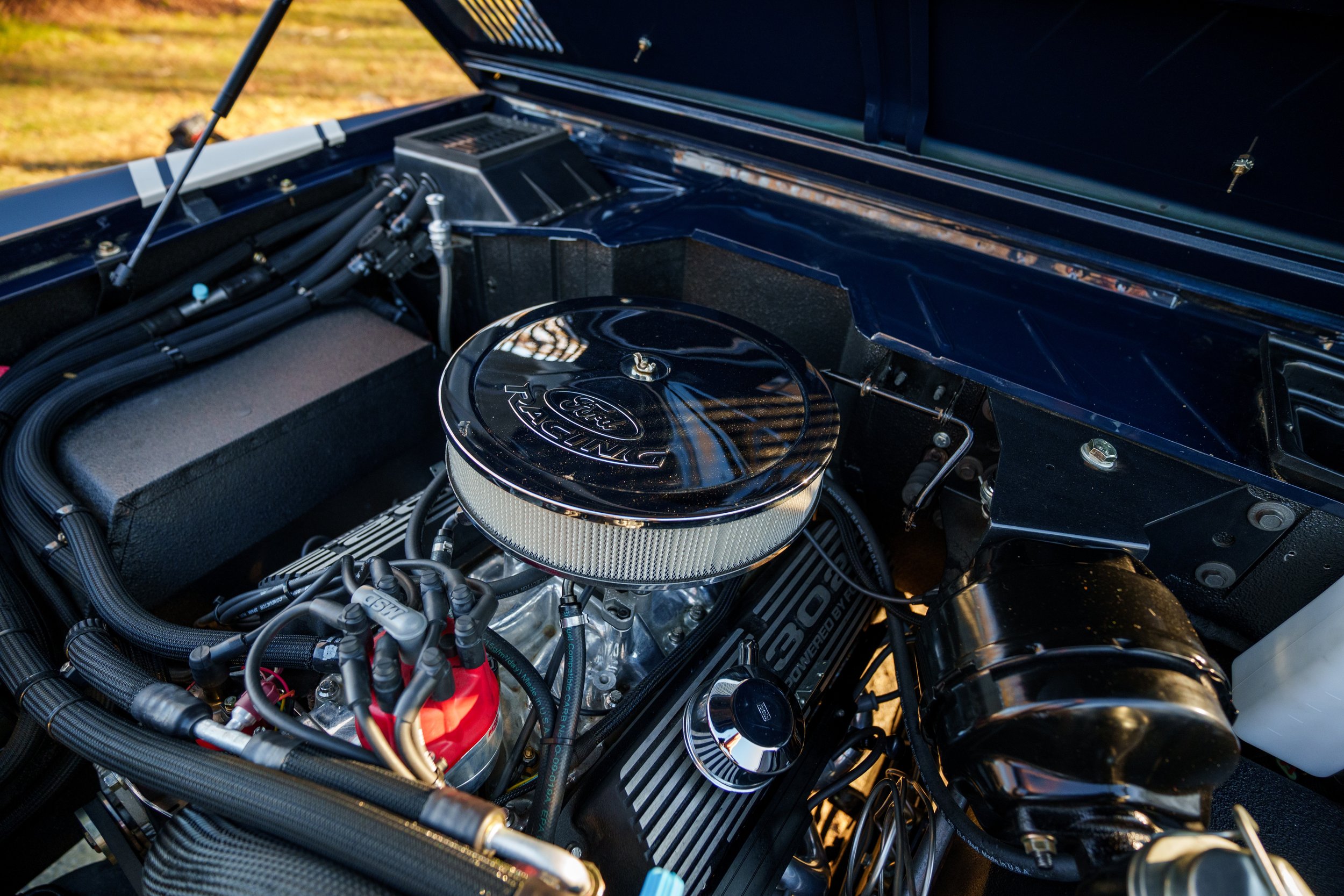

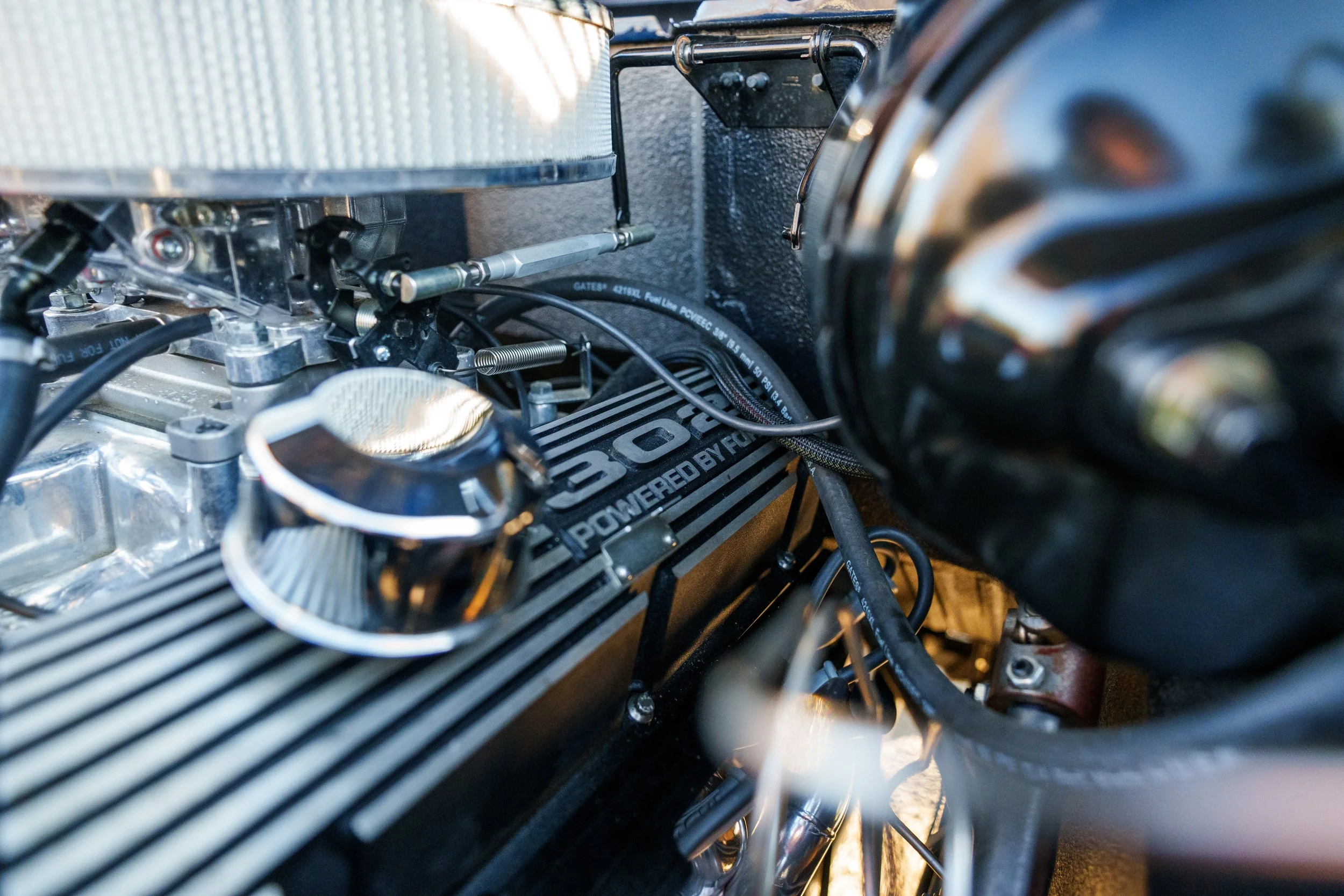

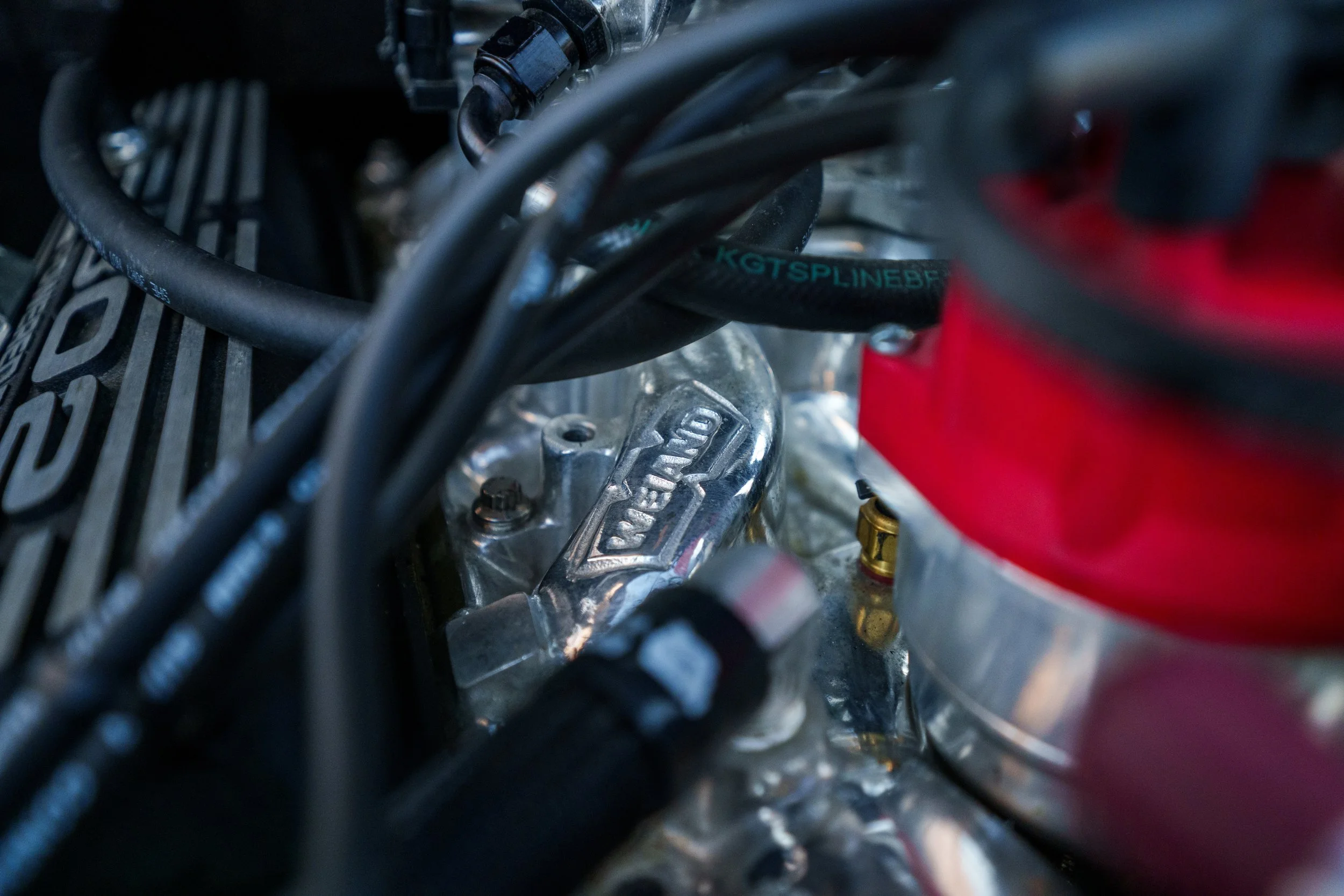

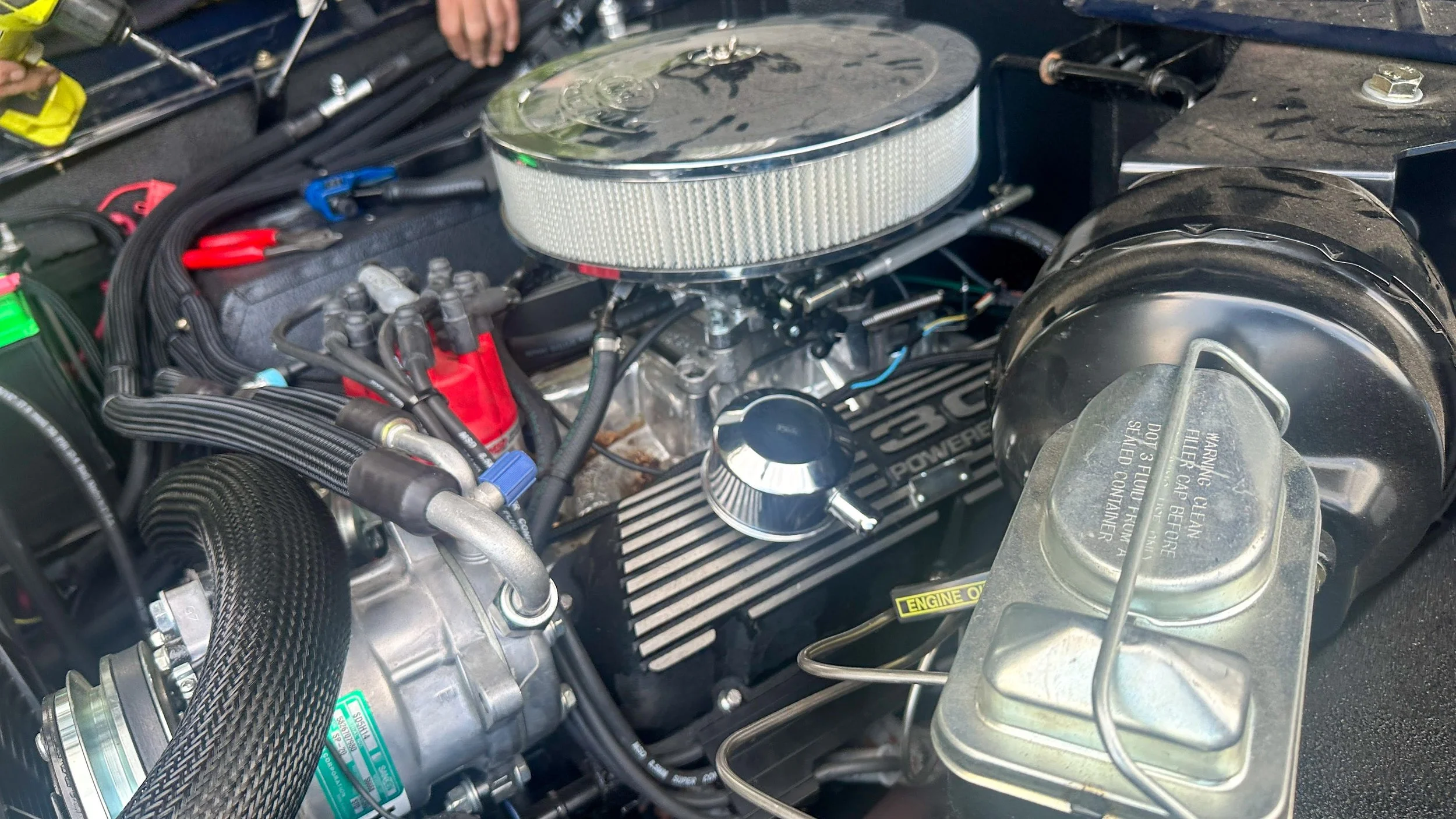

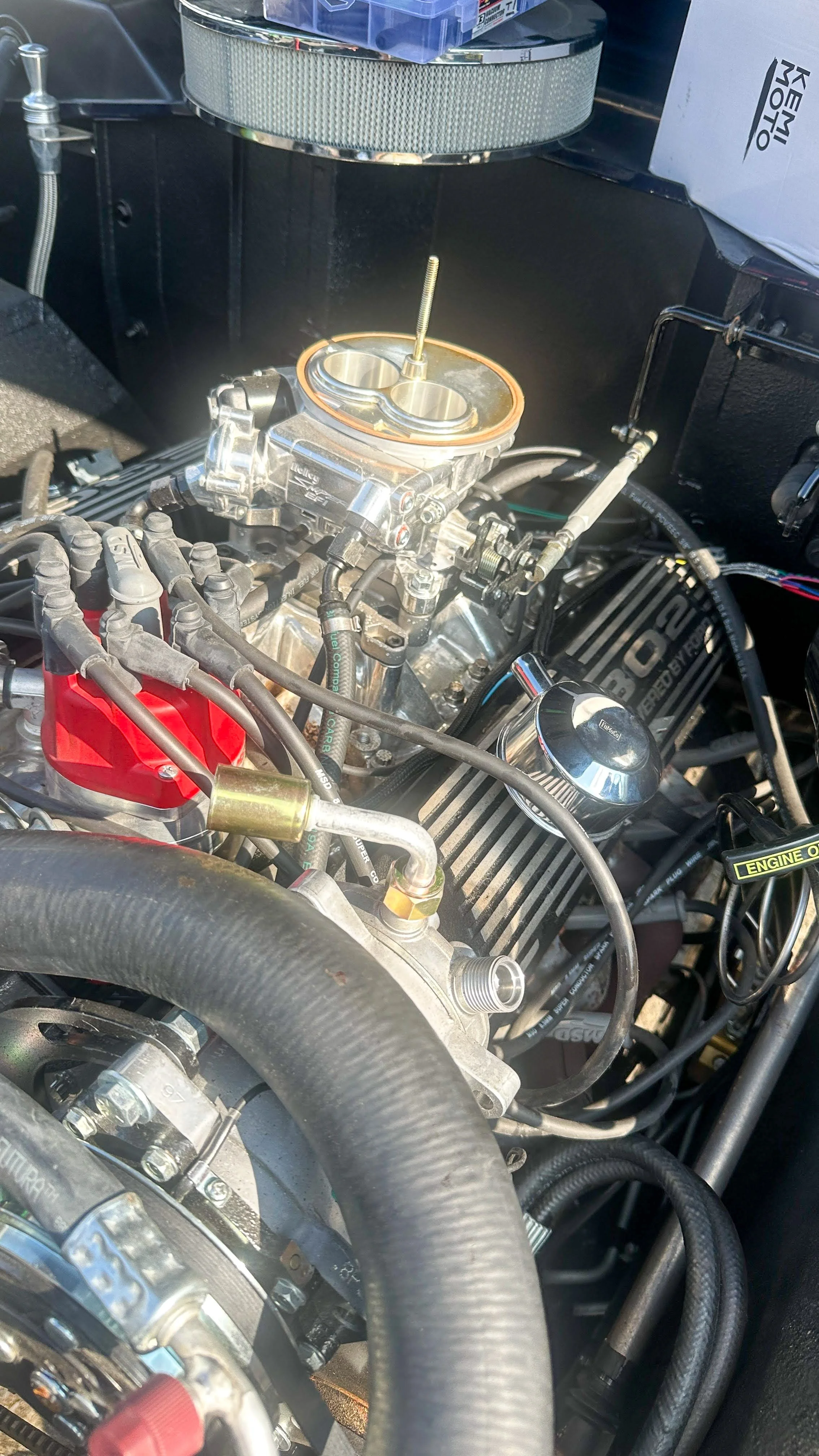

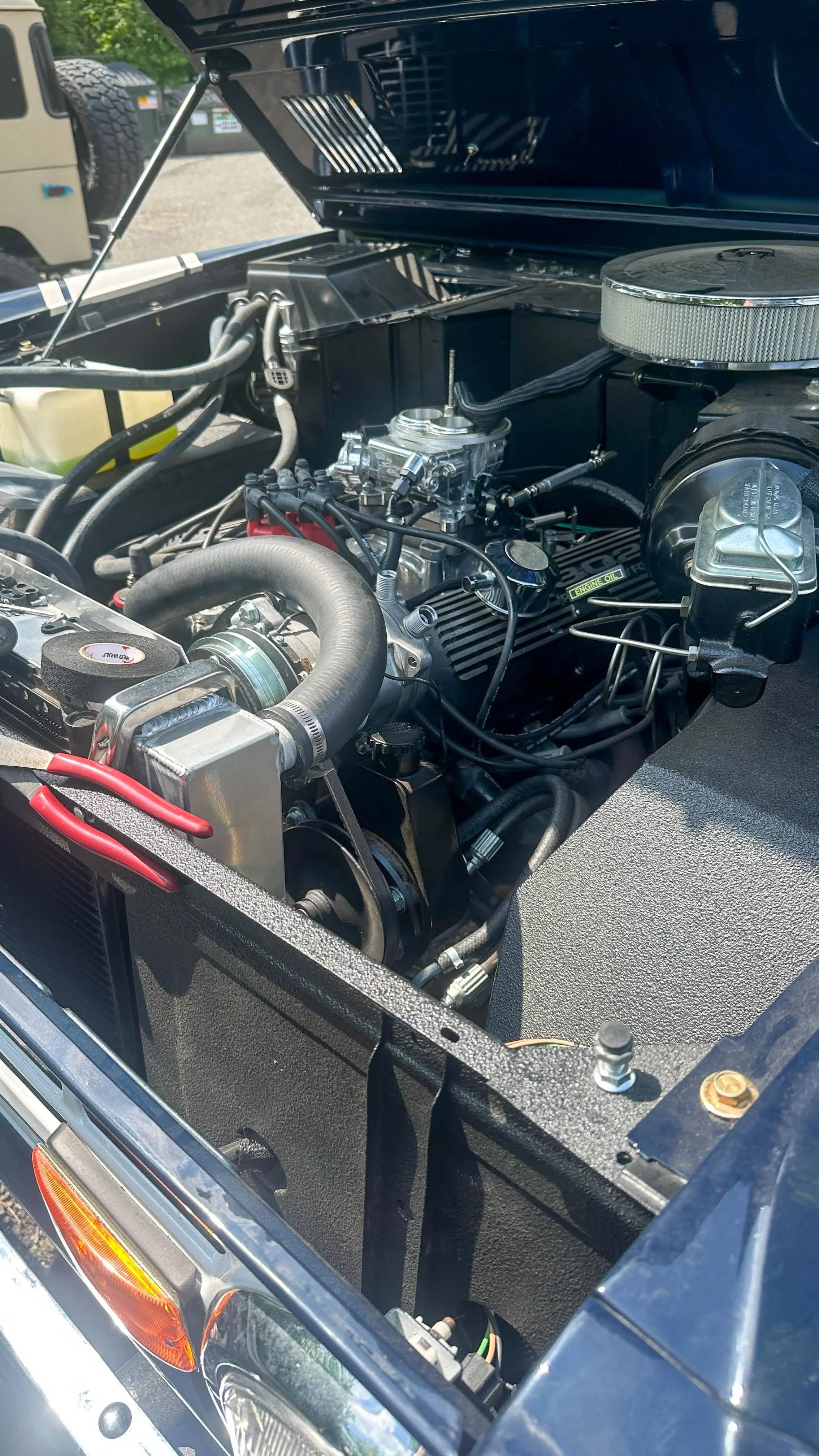

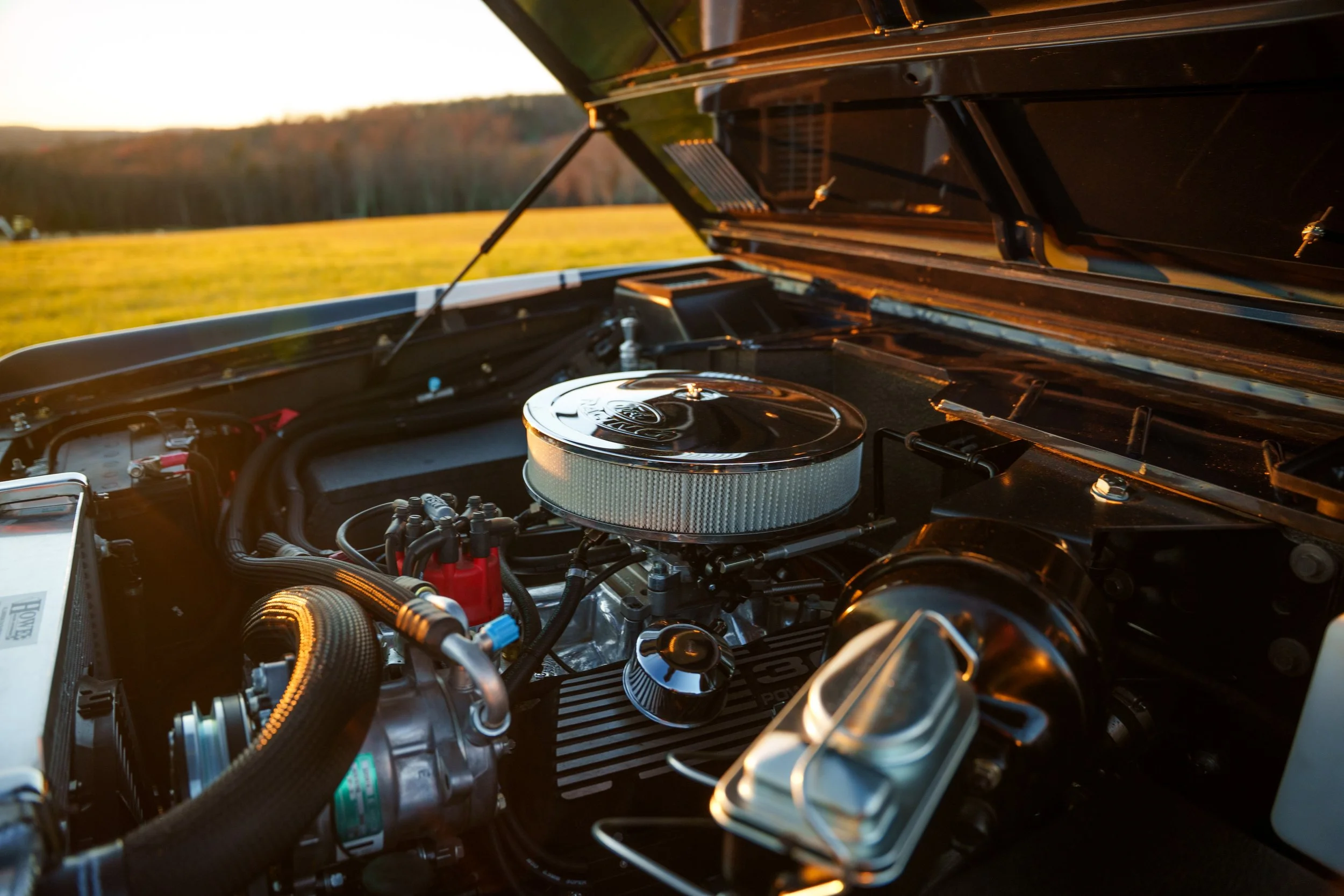

Mechanical

Complete performance exhaust system with new Scott Drake headers

New muffler, flex pipe, hangers, and custom exhaust system

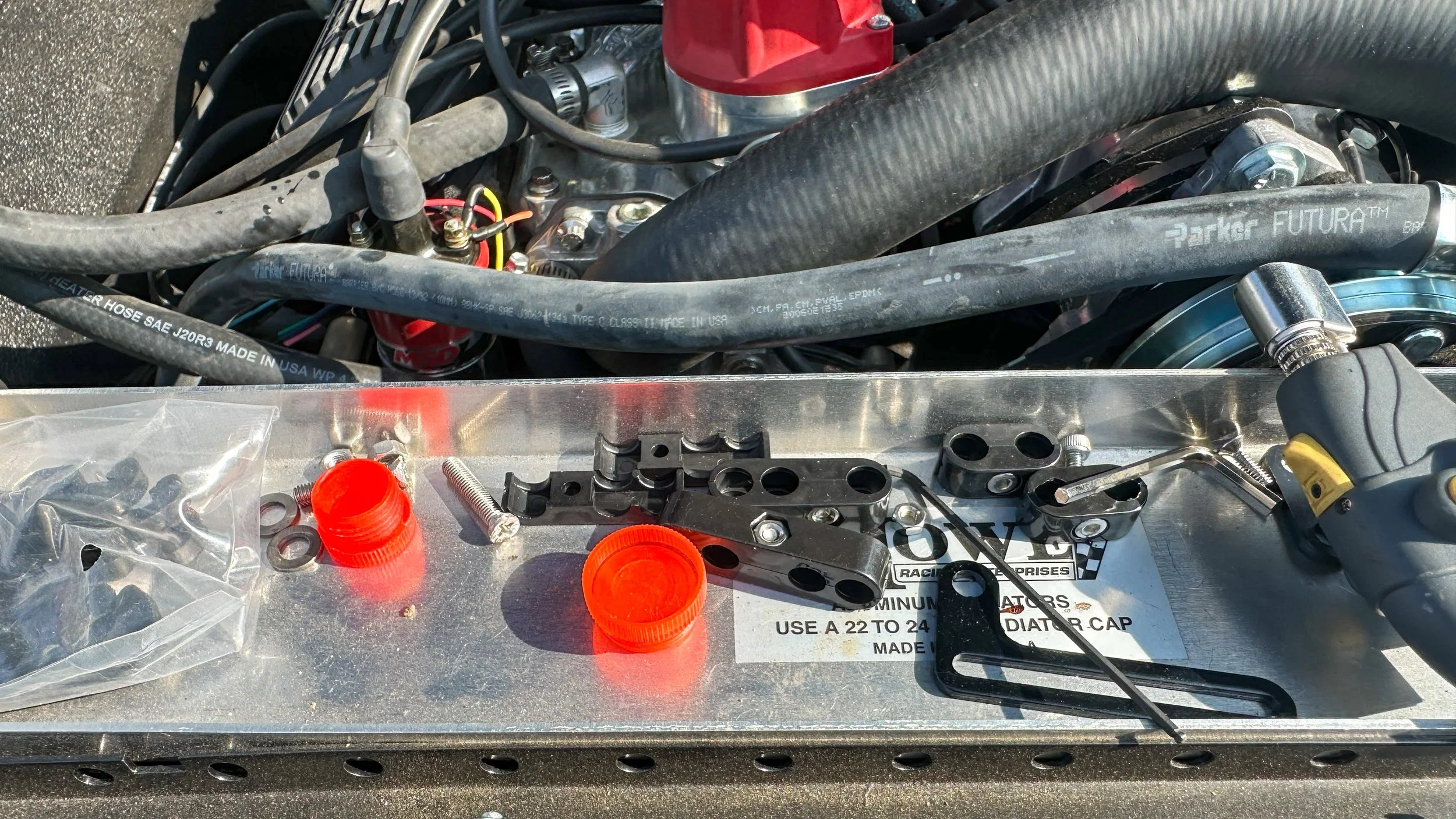

Restored and properly plumbed heating and A/C system

Updated vacuum routing

New engine dipstick and fresh hardware throughout

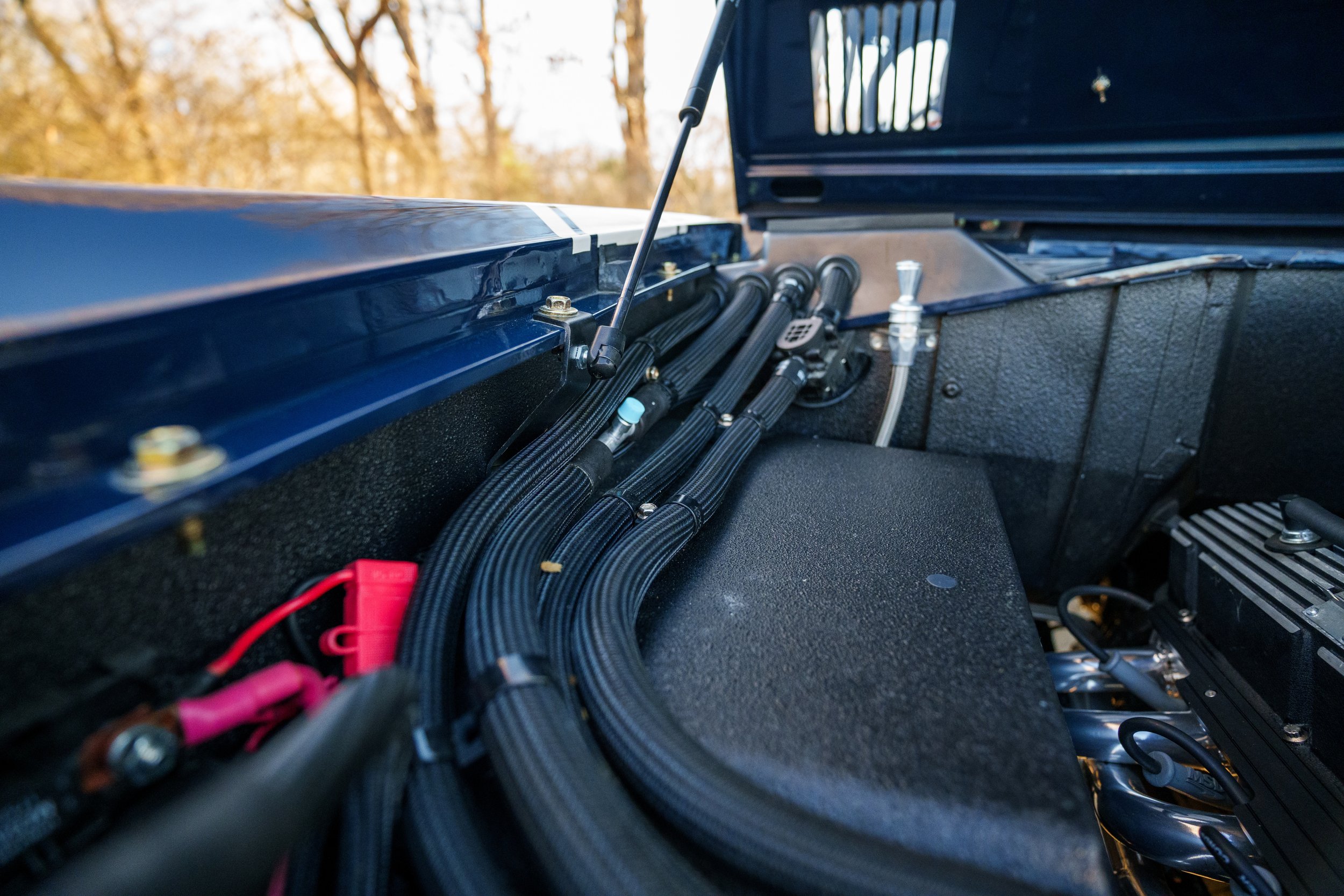

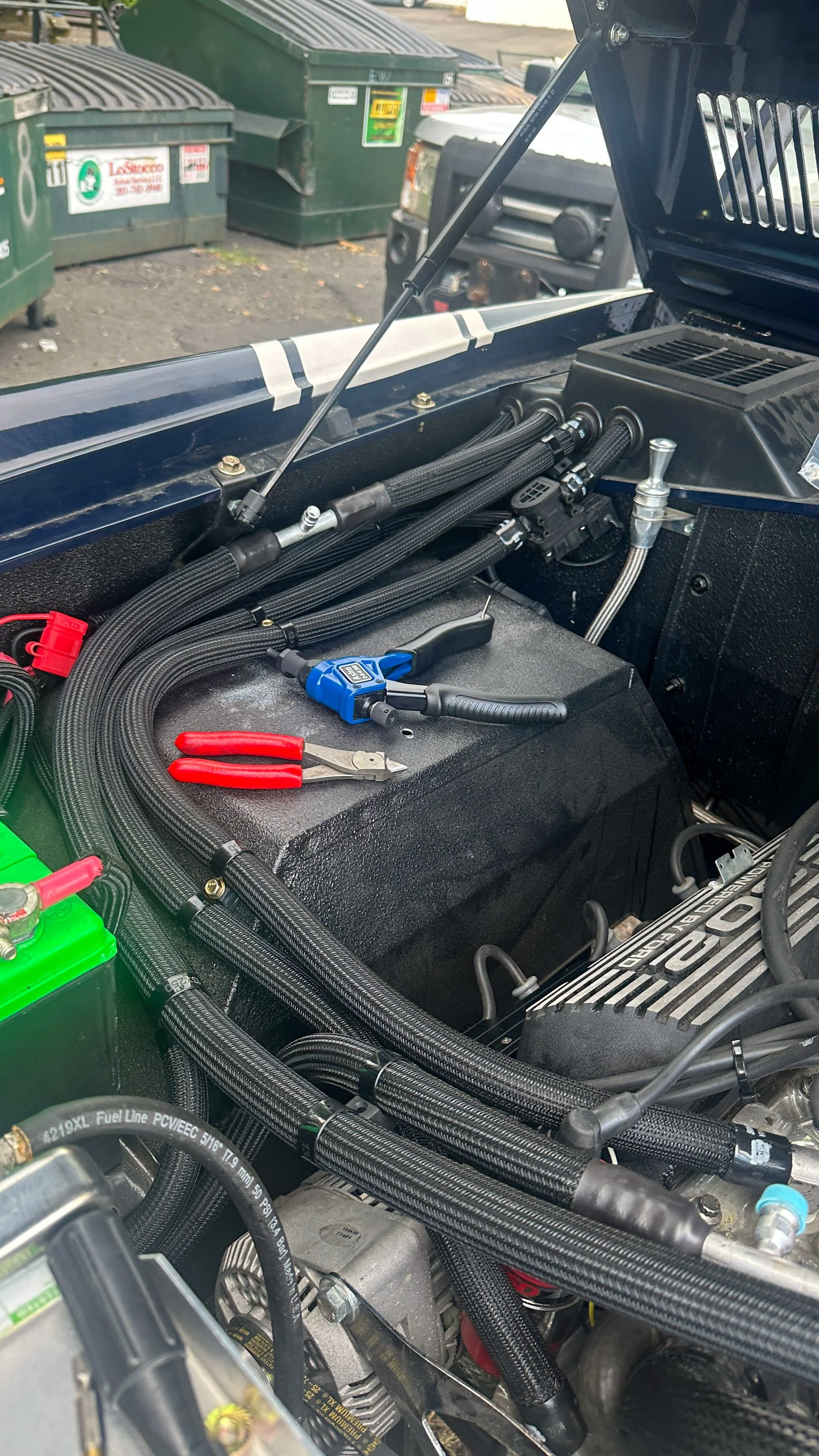

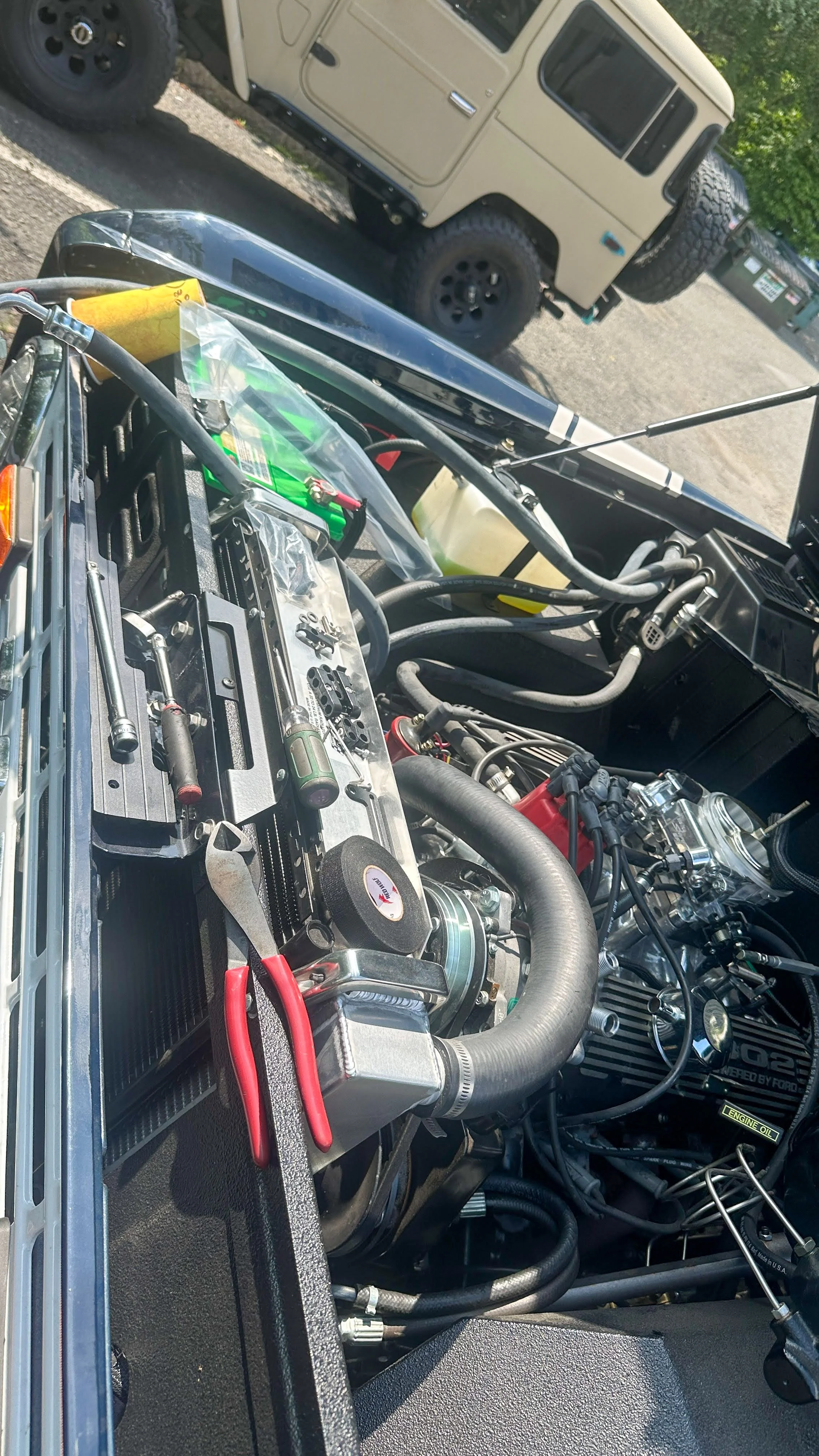

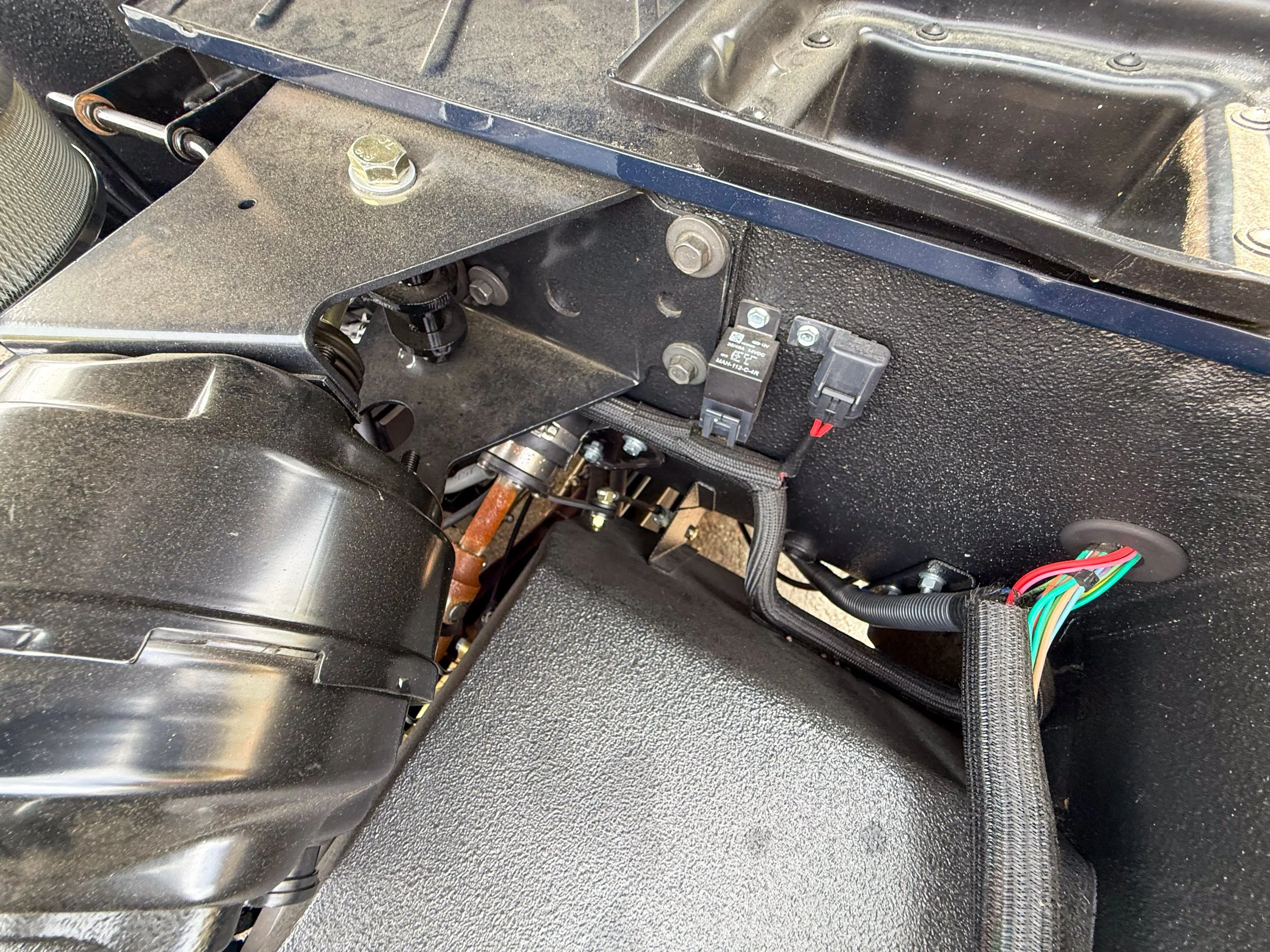

Electrical

Corrected and modernized wiring throughout cabin and engine bay

New fused relay systems, timer switch modules, and updated circuits

Upgraded distribution block and electrical connectors

Refined accessory and horn circuits

Fully verified electrical system with clean routing and proper load management

Interior & Top

Custom soft top with Legacy Overland patterning and precision fit

Reinforced stress points for improved durability

Cleaned and corrected behind-dash wiring and routing

Improved cabin detailing

Finishing & Validation

Multi-stage detailing and surface refinement

Full operational testing of HVAC, electrics, fuel-prime circuit, and exhaust

Road-tested and validated drivability and mechanical systems